HDPE Membrane (full name: High-Density Polyethylene Membrane) is a thermoplastic geosynthetic made of high-density polyethylene resin mixed with anti-UV agents, antioxidants and other additives, processed by extrusion molding. It is widely used for anti-seepage, waterproofing and corrosion resistance in environmental protection, water conservancy, municipal engineering and aquaculture. It features excellent chemical stability, strong anti-puncture ability and long service life. This blog post provides a comprehensive analysis of HDPE membrane prices, ranging from $0.25–$5.50 per square foot ($2.70–$59.20/m²). Bpmgeosynthetics will explain this article in details from cost factors, material types, specifications, installation requirements, and cost-saving strategies to deliver actionable insights for achieving 98% project anti-seepage reliability and 20–30% cost savings.

1. What is HDPE Membrane?

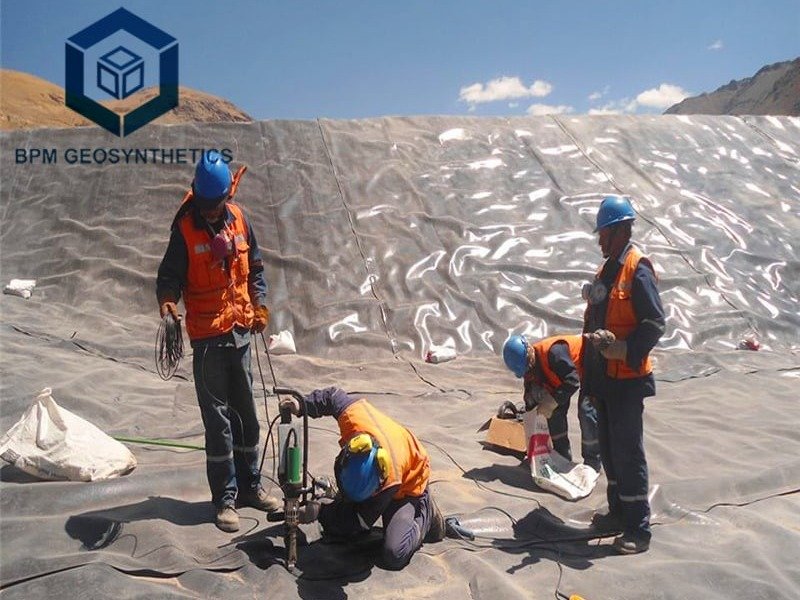

An HDPE Membrane (also known as HDPE Geomembrane) is a flexible, impermeable sheet material made from high-density polyethylene resin (accounting for about 95%) combined with functional additives such as carbon black, anti-aging agents and UV absorbers. Through extrusion molding process, it forms a uniform-thickness membrane with excellent physical and chemical properties. During construction, it is laid on the project base and connected into a continuous anti-seepage system by hot-melt welding or adhesive bonding, which can effectively block the penetration of water or chemical media.

Its core engineering principle is physical impermeability. The dense molecular structure of HDPE liner forms a barrier against fluid penetration, while its good flexibility and elongation enable it to adapt to the uneven settlement of the base and avoid membrane damage caused by ground deformation.

2.Types of HDPE Membrane

HDPE membranes are categorized mainly by material grade, structure design, and application scenario, with the following common types:

2.1. By Material Grade (Most Common Classification)

Virgin HDPE Membrane: The most widely used type (accounting for ~85% of the market). It has stable performance, excellent anti-UV ability and corrosion resistance, with a service life of 50–70 years. Suitable for large-scale projects such as landfills, reservoirs and industrial sewage pools.

Recycled HDPE Membrane: Made from recycled polyethylene materials, cost-effective but with slightly reduced performance. Ideal for temporary anti-seepage projects (e.g., temporary construction water pools) or low-demand scenarios like agricultural irrigation ditches.

Enhanced HDPE Membrane: Added with special reinforcing agents or modified materials, it has higher tensile strength and anti-puncture performance. A premium option for harsh environment projects (e.g., chemical waste landfills, high-pressure water storage facilities).

2.2 By Structure & Design

Smooth HDPE Membrane: With a flat surface, easy to lay and weld, suitable for most general anti-seepage projects. It has good impermeability and is the most common type in the market.

Textured HDPE Membrane: With concave-convex texture on the surface, which increases the friction between the membrane and the base or backfill material, preventing slippage. Perfect for steep slope laying or vertical anti-seepage projects.

Customized HDPE Membrane: Tailored thickness (0.2–3.0mm), width (2–8m) and color for special projects (e.g., large-scale artificial lakes, coastal reclamation anti-seepage).

3.Factors Influencing HDPE Membrane Costs

3.1. Material Grade–HDPE Membrane Price

Virgin HDPE: Stable performance, UV-resistant, widely used, $0.80–$2.90/sq ft.

Recycled HDPE: Cost-effective, light-duty, $0.25–$1.20/sq ft.

Enhanced HDPE: High tensile strength, for harsh environments, higher price than virgin HDPE by 30%–50%.

Imported resin materials: Higher cost, depending on import tariffs and exchange rates.

3.2. Specifications (key parameter impact)–HDPE Membrane Price

Thickness: 0.2–3.0mm common, 1.5mm vs 0.5mm can cost 100%–200% more.

Width: Wider width (6–8m) reduces welding workload but increases production difficulty, with unit cost 15%–30% higher than conventional width (2–4m).

Texture type: Textured HDPE membrane costs 10%–20% more than smooth type due to more complex production process.

Color and additives: Special color or additional functional additives (e.g., high-temperature resistant agents) increase cost by 5%–15%.

3.3. Production & Brand–HDPE Membrane Price

Process: Extrusion molding with online detection technology is 10%–15% pricier than ordinary extrusion, with better product uniformity and lower defect rate.

Brand: Premium brands cost 15%–25% more than generic ones for quality assurance and after-sales service.

3.4. Order Scale & Procurement–HDPE Membrane Price

Bulk orders (≥10,000 sq ft) get 15%–25% discount; small orders have higher unit cost due to fixed production and transportation costs.

Imported vs local: Imported adds tariff/shipping, increasing cost by 25%–45%.

3.5. Installation & Site Conditions (35%–55% of total cost)–HDPE Membrane Price

Site prep: Clearing, leveling and compacting add $0.30–$0.80/sq ft; uneven or rocky terrain raises cost by 50%–100%.

Labor: Urban areas cost $0.40–$1.20/sq ft, rural areas lower; complex terrain (e.g., mountain reservoirs) boosts labor cost.

Welding materials: Hot-melt welding rod cost $0.10–$0.30/sq ft; adhesive for special scenarios is more expensive, $0.20–$0.50/sq ft.

4.HDPE Membrane Price Breakdown

Material: Virgin HDPE $0.80–2.90, recycled HDPE $0.25–1.20, enhanced HDPE $1.20–3.80. Thickness 0.5mm→1.5mm +100%–200%; textured type +10%–20%. Accessories (welding rods, adhesives) $0.10–0.50.

Installation: Site prep $0.30–0.80, labor $0.40–1.20, welding/ bonding $0.10–0.30, equipment rental $0.15–0.40. Complex terrain (rocky/mountainous) boosts prep/labor by 50%–100%.

Logistics & Overhead: Shipping $0.15–0.40 (remote +15%–35%), import tariff $0.25–0.50, admin/tax $0.05–0.25.

Typical totals: Agricultural irrigation $0.80–2.00, artificial lake $2.00–4.50, landfill $3.50–5.50.

5.Applications of HDPE Membrane and Cost Implications

Agricultural Irrigation Ditches/Ponds: Rural areas, total cost $0.80–2.00. Uses recycled/virgin HDPE of 0.5–1.0mm; 50% cheaper than traditional concrete lining, maintenance cost reduced by 70%+.

Municipal Landscape Artificial Lakes: Urban areas, total cost $2.00–4.50. Needs 1.0–1.5mm virgin HDPE, usually textured type for slope stability; reduces construction period by 30% compared with traditional methods, saving labor costs.

Landfill Anti-seepage: Environmental protection projects, total cost $3.50–5.50. Uses 1.5–2.0mm enhanced HDPE with multi-layer laying; although initial cost is high, it avoids leakage risks and subsequent remediation costs, with 30-year lifecycle cost saving 40%–60% compared with other materials.

Reservoir & Dam Anti-seepage: Water conservancy projects, total cost $2.50–5.00. Uses 1.2–2.0mm virgin HDPE; adapts to large-area base laying, welding strength up to 80% of the membrane itself, reducing leakage rate to less than 1%.

Roof Garden Waterproofing: Residential and commercial buildings, total cost $3.00–4.80. Uses 1.0–1.5mm smooth HDPE membrane; non-toxic and environmentally friendly, with strong root resistance, service life 2–3 times longer than ordinary waterproof coatings.

6.Conclusion

HDPE membranes are a cost-effective, versatile solution for anti-seepage and waterproofing projects, offering 50% less cost than traditional concrete lining, 70%+ lower maintenance, and 2–3x longer lifespan than ordinary waterproof materials, with total costs ranging from $0.80–5.50 USD/sq ft. For reliable performance, Xinyu Geosynthetics is highly recommended—a leading manufacturer with rich experience, BPM geosynthetics delivers ASTM/ISO-certified HDPE membranes with <0.5% defect rates, advanced extrusion molding technology for uniform thickness, and customizable specs. With a complete supply network serving domestic and foreign markets, one-stop engineering design and installation guidance, and factory-direct pricing,ensures quality, cost efficiency, and tailored solutions for both light-duty agricultural projects and heavy-duty environmental protection and water conservancy projects.