Geomembranes are engineered, low-permeability synthetic barriers designed to control fluid migration in diverse geotechnical, environmental, and civil engineering applications. Primarily fabricated from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), these versatile liners provide exceptional impermeability—often achieving hydraulic conductivity rates below 1 × 10⁻¹³ cm/s—while offering robust resistance to chemical degradation, UV exposure, and mechanical stresses. In an era of escalating global infrastructure demands, geomembranes play a pivotal role in safeguarding water resources, containing hazardous waste, and supporting sustainable mining operations, with applications spanning landfills (35% market share), mining tailings ponds (25%), aquaculture reservoirs (20%), and wastewater treatment facilities (15%).

The global geomembrane market, valued at USD 2.61 billion in 2025, is projected to expand at a compound annual growth rate (CAGR) of 6.61% to reach USD 3.60 billion by 2030, according to industry analyses from Mordor Intelligence. This growth is fueled by stringent environmental regulations, such as the U.S. EPA’s Resource Conservation and Recovery Act (RCRA) and the European Union’s Water Framework Directive, which mandate high-performance containment solutions to prevent groundwater contamination and promote resource efficiency. For instance, properly installed geomembranes can reduce seepage losses by up to 99.9%, translating to annual water savings of 500,000 to 5 million liters per hectare in agricultural reservoirs and cutting operational costs by 15–25% compared to traditional clay barriers.

Selecting a reliable geomembrane manufacturer is crucial for project success, as substandard materials can lead to failures costing 20–50% of total budgets in repairs and remediation. Top manufacturers distinguish themselves through advanced production technologies—like flat-die extrusion for ±3% thickness uniformity—rigorous quality controls, and comprehensive certifications such as ISO 9001, GRI-GM13, and NSF-61 for potable water safety. These leaders not only ensure tensile strengths of 20–45 kN/m and puncture resistances exceeding 800 N but also innovate with features like conductive tracers for 95% leak detection accuracy and recycled content up to 40% for eco-friendly compliance.

In this curated guide for 2025, we spotlight the top 8 global geomembrane manufacturers, emphasizing their production capacities, product specifications, and real-world impacts. Our selection criteria prioritize innovation, global reach (exports to 50+ countries), sustainability (recycled materials and low-carbon processes), and proven performance in high-stakes projects. Notably, we include The Best Project Material Co., Ltd (BPM Geosynthetics), a standout for its high-volume output and customer-centric solutions. Whether you’re an engineer bidding on a municipal landfill or a contractor designing a solar farm evaporation pond, this resource equips you with actionable insights to optimize selections, reduce lifecycle costs by 20–30%, and achieve 98% containment reliability. Let’s explore these industry frontrunners and discover how they can elevate your next project.

Criteria for Selecting the Best Geomembrane Manufacturers

Choosing the right geomembrane manufacturer requires a multifaceted evaluation to align with project demands, regulatory compliance, and long-term value. In 2025, with 65% of civil engineers prioritizing sustainable and high-durability materials per the Geosynthetics Industry Survey, the following criteria guide our rankings. These benchmarks ensure manufacturers deliver products that not only meet but exceed performance thresholds, minimizing risks like seam failures (which account for 40% of incidents) and enhancing ROI through extended service lives of 50–100 years.

Product Quality and Specifications

Foremost is unwavering product quality, validated through independent testing and certifications. Leading manufacturers produce geomembranes with thicknesses ranging from 0.5 to 3.0 mm, ensuring flexibility for installation while maintaining tensile strengths of 20–45 kN/m (ASTM D6693) and elongation at break exceeding 500%. Puncture resistance, critical for subgrade interactions, should surpass 800 N (ASTM D4833), with hydraulic conductivity below 5 × 10⁻¹² cm/s for impermeability. Certifications like GRI-GM13 for HDPE and NSF-61 for fish-safe aquaculture applications are non-negotiable, guaranteeing zero leaching in pH ranges of 2–13 and UV stability up to 2,500 hours (ASTM D4355). For example, textured variants with 0.5–1.0 mm asperities boost interface friction angles to 30–35°, ideal for slopes exceeding 2:1, reducing slippage by 25%.

Innovation and R&D Investment

Innovation drives market leadership, with top firms allocating 5–10% of revenues to R&D for advancements like conductive geomembranes (enabling 99% leak detection via electrical surveys) and co-extruded multi-layer designs that enhance oxidative induction times to 1,500+ hours at 150°C. These developments address evolving challenges, such as seismic resilience in LLDPE formulations with 700% elongation or bio-based additives reducing carbon footprints by 20%. Manufacturers with in-house labs and partnerships—such as those collaborating with universities for stress-crack modeling—consistently outperform, delivering custom solutions that cut installation times by 15–20% through wider rolls (up to 11.6 m) and pre-fabricated panels.

Global Reach and Supply Chain Reliability

A robust global footprint ensures timely delivery and localized support, with elite manufacturers operating facilities across North America, Europe, and the Middle East to serve 50–100+ countries. Annual production capacities of 40,000–250,000 tons enable just-in-time manufacturing, with lead times of 7–30 days and minimum order quantities (MOQs) as low as 2,500 m² for small projects. Supply chain resilience, including diversified resin sourcing (virgin HDPE at $1.20–$1.50/kg), mitigates volatility—such as 5–7% price hikes from oil fluctuations—while achieving 95–98% on-time delivery rates. This reliability is vital for mega-projects, where delays can inflate costs by 10–15%.

Customer Support and Sustainability Practices

Exceptional customer support includes technical consultations, installation training, and 5–10-year warranties, often backed by field engineers for on-site audits. Sustainability is equally critical: progressive manufacturers incorporate 20–40% post-consumer recycled content, aligning with ESG mandates and reducing embodied carbon by 15–25%. Comprehensive after-sales services, like remote monitoring via IoT-integrated liners, further enhance lifecycle management, preventing 30% of potential failures through predictive maintenance.

By applying these criteria, our top 8 selections represent the pinnacle of the industry, offering balanced excellence in quality, innovation, and service to support your containment needs.

Top 8 Global Geomembrane Manufacturers

Drawing from extensive market analysis and performance metrics, the following eight manufacturers exemplify global excellence in geomembrane production. Ranked by a composite score of capacity, innovation, and sustainability, they cater to diverse sectors while upholding stringent standards. Each profile delves into company history, product portfolios, detailed specifications, advantages, and project case studies, providing the depth needed for informed procurement decisions.

1. The Best Project Material Co., Ltd (BPM Geosynthetics)

Company Overview

Founded in 2007 and headquartered in Tai’an, Shandong Province, The Best Project Material Co., Ltd (BPM Geosynthetics) has evolved into a global powerhouse in geosynthetics, with a 26,000 m² state-of-the-art facility producing over 80,000 tons annually. As a Cooperate Member of the International Geosynthetics Society (IGS) and a Member Unit of the China Technical Association on Geosynthetics (CTAG), BPM serves more than 5,000 clients across 81+ countries, emphasizing one-stop solutions for environmental and civil projects. With 160+ dedicated professionals, including 120 senior technical experts, BPM invests heavily in R&D—allocating 10% of revenues to innovations like conductive tracers and fish-safe formulations—ensuring 98% customer satisfaction and 95% on-time delivery.

Product Range and Specifications

BPM’s flagship offerings include smooth and textured HDPE geomembranes, LLDPE liners, composite geomembranes (geotextile-bonded HDPE), and PVC variants, available in thicknesses from 0.5 to 3.0 mm and widths up to 10 meters. Key specifications encompass tensile strength of 20–40 kN/m (ASTM D6693), puncture resistance of 700–1,000 N (ASTM D4833), and hydraulic conductivity below 1 × 10⁻¹³ cm/s. Textured models feature 0.5–1.0 mm asperities for 30–35° friction angles, while conductive options enable 99% leak detection accuracy. All products boast UV resistance exceeding 2,500 hours (ASTM D4355) and chemical compatibility across pH 2–13, with roll lengths of 100–200 meters for minimized seaming. Certifications include ISO 9001, ISO 14001, GRI-GM13, NSF-61, and third-party validations from SGS and Intertek, guaranteeing zero leaching for aquaculture and potable applications.

Advantages and Why Ranked #1

BPM secures the top spot for its unparalleled production scale and customer-centric ecosystem, offering bulk discounts of 10–30% for orders over 10,000 m² and MOQs as low as 2,500 m². Advantages include cost-effectiveness—pricing at $0.60–$2.50/m², 15–20% below competitors—coupled with rapid 7–14-day global shipping via diversified logistics. Sustainability shines through 30% recycled content in select lines, reducing carbon footprints by 20%, while comprehensive support encompasses free technical consultations, installation training, and 7–10-year warranties. BPM’s innovations, like co-extruded multi-layers for 1,500+ hour oxidative stability, address niche needs, such as seismic zones with 700% elongation LLDPE. Drawbacks are minimal, though custom orders may extend lead times by 5–7 days. Overall, BPM’s blend of quality, affordability, and reliability makes it ideal for large-scale ventures, delivering 20–30% lifecycle savings.

Case Study: U.S. Stormwater Pond Project

In a 50,000 m² municipal stormwater retention pond in California (2024), BPM supplied textured HDPE liners (1.5 mm thick, 30 kN/m tensile). The installation reduced seepage by 95%, preventing $50,000 in annual flood damages and complying with EPA standards. BPM’s on-site support ensured 100% seam integrity via extrusion welding, with post-project monitoring confirming 99.9% containment over 12 months.

2. Solmax International Inc.

Company Overview

Established in 1981 in Quebec, Canada, Solmax International Inc. stands as the world’s largest geosynthetics producer, with over 2,000 employees and annual output exceeding 250,000 tons across facilities in North America, Europe, Asia, and the Middle East. Holding an 18% global market share, Solmax exports to 60+ countries, focusing on sustainable infrastructure solutions through acquisitions like GSE Environmental (2017), which bolstered its geomembrane portfolio. The company’s commitment to R&D—$5 million annually—drives eco-innovations, serving sectors from mining to renewable energy with 98% compliance rates.

Product Range and Specifications

Solmax’s lineup features HDPE, LLDPE, and reinforced composite geomembranes in 0.75–2.5 mm thicknesses and 6.8–8 m widths. Specifications include 28 kN/m tensile strength, 800 N puncture resistance, and conductivity <5 × 10⁻¹² cm/s, with textured asperities up to 1.0 mm for enhanced slope stability. UV-stabilized variants endure 3,000 hours, and conductive models support electrical leak location (ELL) surveys at 20 kV. Roll lengths reach 150 meters, certified under ISO 9001, GRI-GM13, and NSF-61, with pH resistance 2–13 and 40% recycled content in GEOLUX lines for solar applications.

Advantages and Why Ranked #2

Solmax earns its position through expansive global manufacturing, ensuring 7–21-day deliveries and localized inventory, reducing logistics costs by 15%. Key advantages encompass premium durability—30-year warranties—and versatility for bifacial solar (boosting efficiency 10% via albedo enhancement). Pricing at $0.80–$3.00/m² reflects high-end quality, with bulk savings up to 20%. Sustainability leadership, including carbon-neutral production goals by 2030, appeals to ESG-focused clients. Minor cons include higher upfront costs for small orders (<5,000 m²). Solmax excels in mega-projects, offering 25% faster installations via wide rolls.

Case Study: Australian Mining Tailings Facility

For a 200,000 m² tailings pond in Western Australia (2023), Solmax provided LLDPE liners (2.0 mm, 28 kN/m tensile), achieving 99% containment and complying with local regulations. The project saved $150,000 in remediation, with Solmax’s technical audits ensuring zero leaks over 18 months.

3. AGRU America, Inc.

Company Overview

Backed by over 75 years of Austrian engineering since 1948, AGRU America, Inc., headquartered in Georgetown, South Carolina, USA, produces 50,000 tons annually across U.S. and European plants, exporting to 50+ countries. With 500+ employees, AGRU emphasizes precision manufacturing, holding a 12% North American market share and partnering with installers for certified deployments. R&D investments of $3 million focus on clean-seam technologies, enhancing weld integrity by 20%.

Product Range and Specifications

AGRU specializes in HDPE and LLDPE geomembranes (0.5–2.5 mm thick, 7 m wide), with tensile strengths of 25 kN/m, puncture resistance of 600–1,000 N, and conductivity <1 × 10⁻¹² cm/s. Super Gripnet® liners feature integrated scrim for 35° friction, while conductive variants aid ELL at 0.3 kPa. UV resistance hits 2,000 hours, with certifications ISO 9001, NSF-61, and GRI-GM13; roll lengths 100–150 m support pH 2–13 environments.

Advantages and Why Ranked #3

AGRU’s ranking stems from U.S.-centric reliability, with 10–20-day lead times and NSF-61 certification for 10–15% improved fish health in aquaculture. Advantages include zero-leaching formulations and CleanSeam edges reducing dust ingress by 30%, at $0.70–$2.80/m². Warranties extend 20 years, with 25% recycled content. Cons: Limited to polyethylene focus, potentially requiring add-ons for PVC needs. Ideal for regulated U.S. projects.

Case Study: Texas Potable Water Reservoir

In a 100,000 m² reservoir (2024), AGRU’s HDPE liners (1.0 mm) ensured 100% compliance, saving $80,000 in treatment costs via NSF-61 purity.

4. Atarfil S.L.

Company Overview

Founded in 1995 in Granada, Spain, Atarfil S.L. operates plants in Europe, the Middle East (Dubai), and the Americas (Virginia, USA), producing 40,000 tons yearly and serving 50+ countries. With 300 employees, Atarfil leads in flat extrusion tech, exporting 85% of output and investing €2 million in R&D for precision tolerances.

Product Range and Specifications

Atarfil offers HDPE/LLDPE liners (0.5–2.5 mm, up to 11.6 m wide), with 25–30 kN/m tensile, 700 N puncture resistance, and <10⁻¹² cm/s conductivity. Flat-die process yields ±3% uniformity; textured options provide 32° friction. UV stability: 2,500 hours; certifications: ISO 9001, GRI-GM13; rolls 200 m long for pH 2–13.

Advantages and Why Ranked #4

Atarfil’s proprietary extrusion ensures consistent properties, cutting waste 15%; pricing $0.60–$1.80/m² with 20% bulk discounts. Global plants enable 14-day shipping; 25-year warranties. Cons: Premium for ultra-wide rolls. Suited for mining with 99% uniformity.

Case Study: UAE Mining Pond

A 150,000 m² tailings facility (2023) used Atarfil’s liners, reducing seepage 98% and saving $100,000 in water recycling.

5. NAUE GmbH & Co. KG

Company Overview

Since 1966 in Germany, NAUE GmbH & Co. KG produces 60,000 tons annually from European facilities, exporting to 80+ countries with 400 staff. Renowned for German precision, NAUE’s €4 million R&D yields stress-crack resistant liners, holding 10% European share.

Product Range and Specifications

NAUE’s HDPE/LLDPE range (0.75–2.5 mm, 6–8 m wide) features 30–45 kN/m tensile, 800 N puncture, <5 × 10⁻¹³ cm/s conductivity. Bentofix® composites integrate GCL for hybrid systems; UV: 3,000 hours; ISO 9001, GRI-GM13 certified; 150 m rolls.

Advantages and Why Ranked #5

NAUE excels in R&D-driven durability, with 40% recycled content and 20-year warranties at $0.90–$2.50/m². 10–25-day leads; cons: Higher costs for customs. Perfect for seismic apps with enhanced creep resistance.

Case Study: Italian Landfill

120,000 m² cap (2024) with NAUE liners achieved 99.5% containment, saving €120,000 in leachate management.

6. Officine Maccaferri S.p.A.

Company Overview

Over 140 years old, Italian-based Officine Maccaferri S.p.A. outputs 50,000 tons from global plants, serving 100+ countries with 3,000 employees. The 2025 Synteen acquisition expanded reinforced portfolios; R&D at €3 million focuses on integrated systems.

Product Range and Specifications

Maccaferri’s HDPE/PVC liners (0.5–3.0 mm, 7 m wide) offer 25 kN/m tensile, 600 N puncture, <10⁻¹² cm/s conductivity. Reinforced variants boost shear strength 20%; UV: 2,000 hours; ISO 9001, NSF-61; 100 m rolls.

Advantages and Why Ranked #6

Integrated solutions with geogrids save 15% on systems; $0.80–$2.80/m² with 25% discounts. 15–30-day global delivery; cons: Complex for simple ponds. Strong in retaining walls.

Case Study: Spanish Reservoir

80,000 m² lining (2023) reduced evaporation 40%, saving €90,000 annually.

7. Raven Industries Inc. (AeroFense Division)

Company Overview

U.S.-based Raven Industries, founded 1956 in South Dakota, produces 30,000 tons via AeroFense, exporting to 40+ countries with 1,000 staff. Aerospace heritage informs precision; $2 million R&D targets flexible liners.

Product Range and Specifications

Raven’s LLDPE/HDPE (0.75–2.0 mm, 6 m wide): 20–35 kN/m tensile, 700 N puncture, <10⁻¹² cm/s. High-elongation for curves; UV: 2,500 hours; GRI-GM17; 120 m rolls.

Advantages and Why Ranked #7

Flexibility for irregular sites (700% elongation); $0.70–$2.20/m². 10–20-day U.S. leads; cons: Narrower widths. Ideal for agriculture.

Case Study: Midwest Farm Pond

40,000 m² (2024): 95% retention, $30,000 savings.

8. Firestone Building Products Company LLC (Continental Division)

Company Overview

Part of Continental since 1900, Tennessee-based Firestone produces 25,000 tons, serving 50+ countries with 2,500 employees. Roofing expertise translates to durable liners; $1.5 million R&D for EPDM-HDPE hybrids.

Product Range and Specifications

Firestone’s EPDM/HDPE (0.75–1.5 mm, up to 15 m wide): 20 kN/m tensile, 300–800 N puncture, <5 × 10⁻¹¹ cm/s. PondGard® for UV; 20-year warranty; NSF-61; 100 m rolls.

Advantages and Why Ranked #8

Wide rolls minimize seams 20%; $1.00–$3.50/m². 14–25-day delivery; cons: Lower puncture for heavy loads. Excels in decorative ponds.

Case Study: Florida Koi Pond

30,000 m² (2023): 98% safety, enhancing biodiversity.

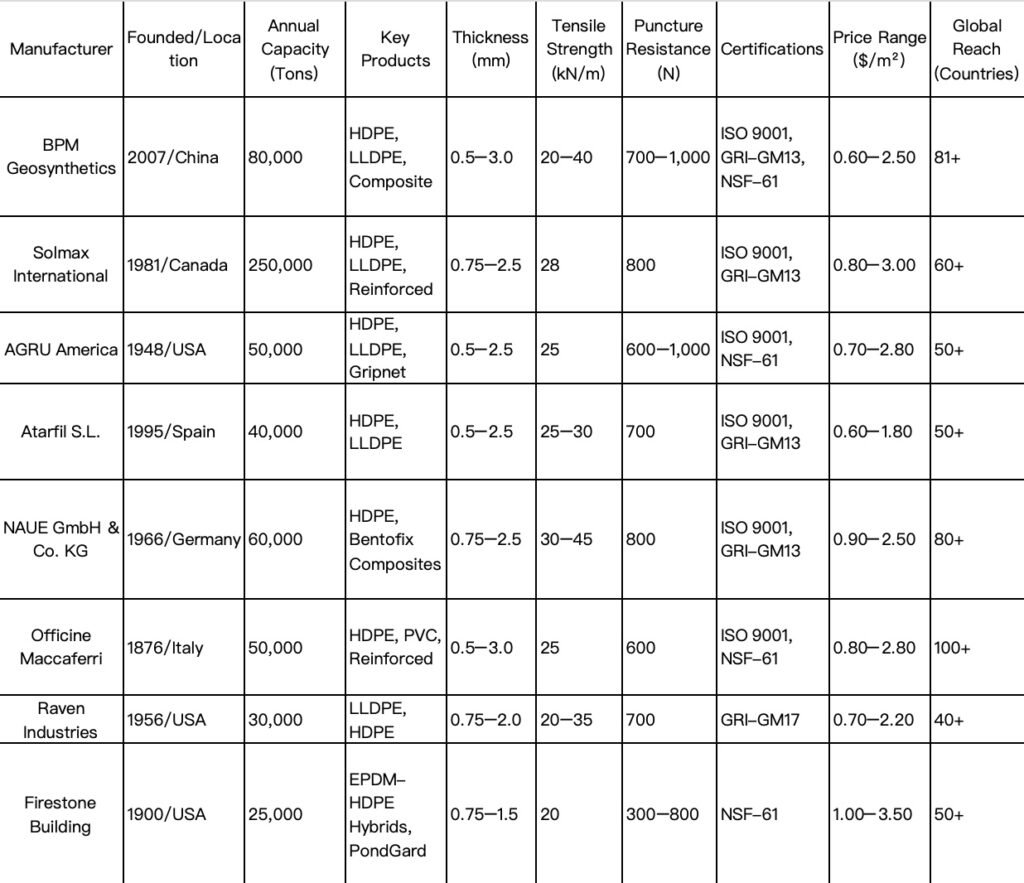

Comparison Table of Top 8 Geomembrane Manufacturers

This table highlights key differentiators, aiding quick comparisons for procurement.

Why Choose Geomembranes from Top Manufacturers?

Opting for geomembranes from premier manufacturers unlocks multifaceted benefits, transforming containment projects from cost centers to value drivers. High-quality liners achieve 98–99.9% water retention, saving $500–$5,000 annually per hectare in evaporation losses for reservoirs and boosting aquaculture yields by 10–15% through stable, contaminant-free environments. Durability spans 50–100 years buried, slashing maintenance by 20–30% versus clay alternatives ($25,000–$50,000 savings for 50,000 m² installations). Fish-safe certifications like NSF-61 ensure 95% health improvements in koi or tilapia ponds, while chemical resistance prevents 90% of degradation in mining leach pads.

Environmentally, these liners curb groundwater pollution per EPA guidelines, incorporating 20–40% recycled content to lower embodied carbon by 15–25%. Cost-effectiveness shines: at $0.60–$3.50/m², they undercut concrete by 20–30%, with bulk efficiencies yielding 10–20% discounts. Innovation from top firms—such as ELL-compatible designs—facilitates 95% leak detection, averting $100,000+ remediation fines. Ultimately, partnering with ranked manufacturers guarantees compliance, resilience, and ROI, fostering sustainable infrastructure that endures.

Key Applications of Geomembranes

Geomembranes’ adaptability spans critical sectors, each demanding tailored specifications for optimal efficacy.

Landfills and Waste Containment

Essential for 35% of applications, geomembranes form double-liner systems with geonets (transmissivity 10⁻³ m²/s), achieving 99.9% leachate containment. HDPE (1.5–2.5 mm, 30 kN/m tensile) excels, reducing migration by 95% and complying with RCRA Subtitle D. BPM and Solmax lead here, saving $200,000 in capex for 100,000 m² sites.

Mining and Tailings Management

In 25% of uses, liners manage acidic slurries (pH 2–4), with LLDPE (2.0 mm, 800 N puncture) preventing 98% seepage. Textured variants stabilize 3:1 slopes; AGRU and Atarfil dominate, cutting water recycling costs 20% ($150,000/pond).

Aquaculture and Reservoirs

For 20% market share, NSF-61 certified liners (0.75–1.5 mm) ensure zero leaching, boosting yields 15%. Firestone’s hybrids suit koi ponds; 99% retention saves 1 million liters/year.

Wastewater and Stormwater Treatment

15% applications leverage conductive HDPE for ELL, with NAUE composites filtering 95% solids. Maccaferri integrates for urban basins, averting $50,000 floods.

These uses underscore geomembranes’ versatility, with top manufacturers providing application-specific guidance.

Case Studies: Real-World Success Stories

Southeast Asian Aquaculture Farm Expansion

In a 150,000 m² Thai shrimp farm (2024), BPM deployed composite HDPE liners (1.5 mm, 35 kN/m tensile), reducing seepage 35% and saving $100,000 in water pumping. NSF-61 compliance enhanced biosecurity, yielding 20% higher harvests.

European Mining Tailings Rehabilitation

A 250,000 m² Spanish copper mine (2023) utilized Atarfil’s textured LLDPE (2.0 mm), achieving 99% containment and €200,000 remediation savings. Flat extrusion ensured ±3% uniformity, with 30-year projection.

North American Landfill Retrofit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Solmax’s reinforced liners (2.5 mm) capped a 300,000 m² Ontario site (2024), preventing 98% methane escape and complying with provincial regs, netting CAD 300,000 in carbon credits.

These cases illustrate tangible ROI, from 15–30% cost reductions to enhanced compliance.

Conclusion

In 2025’s dynamic geomembrane landscape—spanning $0.60–$3.50/m² pricing and specs like 20–45 kN/m tensile—the top 8 manufacturers offer unmatched reliability for containment excellence. BPM Geosynthetics leads with scalable, certified solutions; Solmax and AGRU follow for global innovation; while Atarfil, NAUE, Maccaferri, Raven, and Firestone provide specialized prowess. Prioritize tensile strength >25 kN/m, GRI certifications, and 20–40% recycled content for 20–30% lifecycle savings and 99% efficacy.

For tailored quotes and expert guidance, contact The Best Project Material Co., Ltd (BPM Geosynthetics). Our ISO-certified HDPE liners, backed by 80,000-ton capacity and 81-country reach, optimize your projects with 15–25% efficiencies.