Share:

Textured geomembrane liner is the specially designed geo liner which offers a superior solution for applications requiring enhanced stability and friction. Their unique one or double sided textured surface, combined with the inherent durability and chemical resistance of materials like HDPE, makes them a reliable and long-lasting choice for a wide range of civil and environmental engineering projects. From landfills and mining operations to retaining walls and containment systems, textured geomembranes provide the performance and reliability needed to ensure the safety and integrity of critical infrastructure and environmental protection systems. Their ability to allow for steeper slopes, improve interface friction, and increase shear strength makes them an invaluable tool for engineers and project managers seeking optimal performance and long-term stability.

Looking For Best geomembrane LLDPE Liners At Best Factory Price? BPM Geosynthetics Is the best Geomembrane And Geotextile Manufacturer and Factory offering Best Solution for Global Customers.

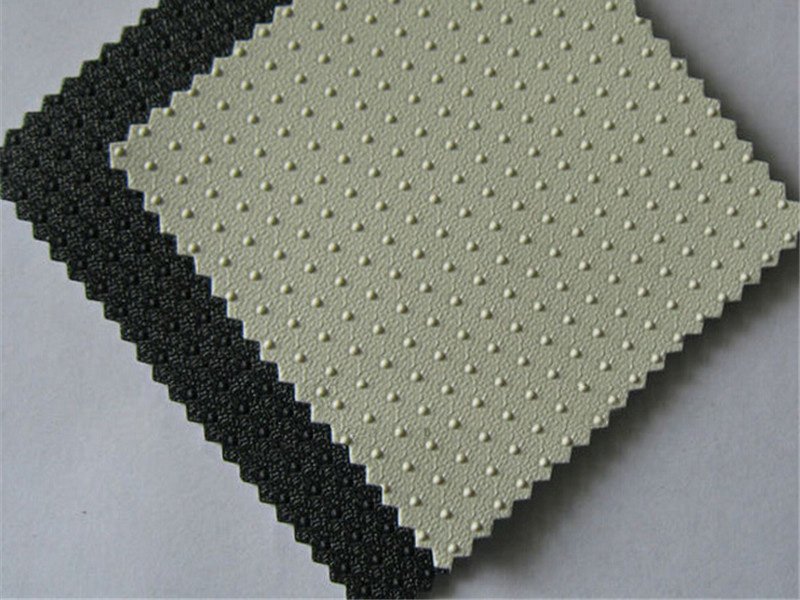

A textured geomembrane liner is a low-permeability synthetic membrane, typically made from high-density polyethylene (HDPE), designed to control fluid or gas migration in geotechnical engineering projects. Unlike smooth geomembranes, textured liners feature a roughened surface on one or both sides, created through processes like roller embossing, nitrogen gas bubble texturing, or sprayed fiber application. This texture increases the friction angle, providing 30-35% better stability on slopes compared to smooth liners, per ASTM D5321 testing. Manufactured using advanced blown-film, calendaring technology or Nitrogen Gas technology, textured geomembranes meet stringent standards like GRI-GM13, ensuring 99.5% quality consistency.

Textured geomembrane liners are primarily composed of 97.5% virgin HDPE resin, combined with 2.5% additives like carbon black, antioxidants, and UV stabilizers. The texturing process enhances surface roughness, with asperity heights ranging from 0.25-0.5 mm, improving interface friction with soils or geotextiles. Leading manufacturers like BPM Geosynthetics utilize state-of-the-art production lines, achieving ±5% thickness control and ±1% size accuracy, per ISO9001 standards. Available in thicknesses from 0.5-2.0 mm and widths up to 8 m, these liners are tailored for diverse project requirements.

Textured geomembranes are crucial in various engineering applications, particularly in environments requiring specific surface characteristics. Here’s an in-depth look at three key types made by BPM Geosynthetics: Blown Film Textured Geomembrane, Calendaring Technology Textured Geomembrane, and Nitrogen Gas Technology Textured Geomembrane.

Process Principle:

Blown film technology extrudes molten polymer through a circular die to form a tube, which is then inflated into a bubble. As it cools and collapses into a flat sheet, the stretching creates a textured surface. Adjustments in inflation pressure and cooling rates can enhance this texture.

Process Principle:

Calendaring involves passing the polymer through heated rollers that compress and smooth the material into a sheet. Textures are formed by using rollers with specific patterns, applying heat and pressure to create the desired surface.

Process Principle:

This method incorporates nitrogen gas into the polymer during extrusion. Tiny bubbles form and burst upon cooling, creating a textured surface. This process can be combined with other techniques to enhance texture and performance.

No | Type of Textured Geomembrane | Process Principle | Advantages | Disadvantages |

1 | Blown Film Textured Geomembrane | Extrusion through a circular die, creating a bubble | Uniform texture, high flexibility, cost-effective | May have lower durability than calendared products |

2 | Calendaring Technology Textured Geomembrane | Heated rollers with specific patterns | High precision, controlled thickness, durability | Higher production cost, less flexibility |

3 | Nitrogen Gas Technology Textured Geomembrane | Incorporating nitrogen gas during extrusion | One-step formation, customizable texture, environmentally friendly | May affect mechanical properties, complex process |

Each type of textured geomembrane offers distinct advantages suited to specific applications. Blown film textured geomembranes excel in flexibility and cost-effectiveness, calendaring technology provides high precision and durability, while nitrogen gas technology emphasizes environmental friendliness and customization. When selecting the right geomembrane, consider application requirements, budget constraints, and environmental impact.

Among them, Blown Film Textured Geomembranes are among the most widely used types of textured geomembranes in various engineering applications. Their unique manufacturing process and versatile characteristics make them suitable for a range of environments where durability and flexibility are critical. Let take Blown Film Textured Geomembrane as the main production to extend the following description.

Item | Specification | |||||

resin thickness of middle fabric mm > | h | l | p | g | gl | |

0.40 | ||||||

Tension | Maximum tension N/cm > | 120 | 250 | 120 | ||

Tension strength MPa > | 10 | 10 | ||||

Maximum tension elongation %> | 15 | |||||

Fracture elongation %> | 200 | 150 | 200 | 100 | ||

Heat treatment size change rate %≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

Low-temperature bending | No craze -25℃ | |||||

Water tightness | No seepage 0.3 Mpa, 2h | |||||

Remark: Any other technical data sheets, please contact us. | ||||||

The advantages of using textured geomembrane liners are numerous:

The life expectancy of a textured geomembrane is substantial, often exceeding 50 years, and in some cases, reaching 75 years or more. This longevity is attributed to the inherent durability of the materials used, primarily high-density polyethylene (HDPE), combined with the added protection provided by the textured surface.

Several factors contribute to this extended lifespan:

Load and Stress: The amount of load and stress the geomembrane is subjected to also affects its lifespan. Applications with high loads or significant movement may require thicker or reinforced geomembranes.

Textured geomembrane liners find widespread use in various civil and environmental engineering applications, including:

Tunnel Linings: Providing waterproofing and stability in tunnel construction.

BPM Geosynthetics, as one of the largest geo liner manufacturers and companies in China, is renowned for strong geomembrane liners and geotextile liners manufacturing alibilities. We offer complete range of best quality geomembranes, geotextiles and related geosynthetic liners at competitive factory price for your environmental, civil engineering and mining applications.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbanes, geotextiles or other geosynthetic liner products or services, please fill in the form, we are always here repond to your inquiries as soon as possible.