Share:

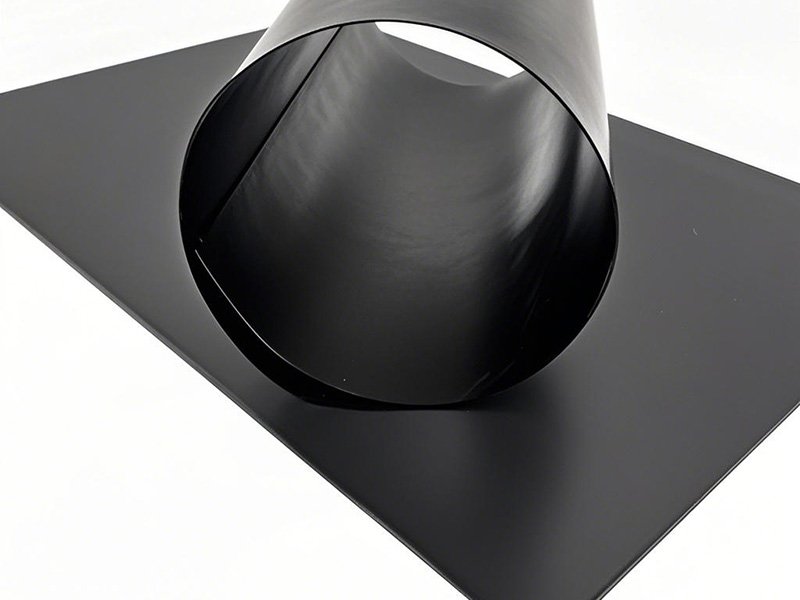

The Low-Density Polyethylene (LDPE) geomembrane liner is a flexible, cost-effective, and reliable synthetic membrane designed for containment applications in environmental, agricultural, and civil engineering projects. Known for its exceptional flexibility, ease of installation, and resistance to environmental stresses, LDPE liners are ideal for projects requiring adaptability to irregular surfaces, such as aquaculture ponds, canals, and temporary containment systems. As a trusted geo liner manufacturer nd supplier, BPM Geosynthetics offesr LDPE geomembrane liners that meet ASTM D7176 standards, ensuring quality and performance.

Looking For Best geomembrane LLDPE Liners At Best Factory Price? BPM Geosynthetics Is The best Geomembrane And Geotextile Manufacturer and Factory offering Best Solution for Global Customers.

LDPE geomembrane liners are manufactured from high-quality polyethylene resins through a process that results in a material with significant flexibility and conformability. The molecular structure of LDPE, characterized by numerous long and short branches, contributes to its lower density and increased flexibility compared to other polyethylene variants. This inherent flexibility allows LDPE geomembranes to easily adapt to uneven subgrades and complex contours, making them a versatile solution for various projects requiring reliable containment. Typically, LDPE geomembranes are formulated with additives such as carbon black for UV resistance, antioxidants for thermal stability, and other stabilizers to enhance their performance and longevity in demanding environments. The base polymer generally constitutes the majority of the liner’s composition, with the additives carefully selected to optimize specific performance characteristics.

No. |

Item |

Unit | Thickness | ||||||

0.3mm | 0.5mm | 0.75mm | 1.0mm | 1.25mm | 1.5mm | 2.0mm | |||

1 | Density | (g/cm3) | 0.939 | ||||||

2 | Tensile strength at break(MD/CD) | (N/mm≥) | 6 | 9 | 14 | 19 | 23 | 28 | 37 |

3 | Elongation (MD/CD) | (%≥) | 560 | ||||||

4 | Tear strength (MD/CD) | (N≥) | 27 | 45 | 63 | 90 | 108 | 135 | 180 |

5 | Puncture strength | (N) | 52 | 84 | 135 | 175 | 220 | 260 | 350 |

6 | Carbon black content | (%) | 2.0~3.0 | ||||||

7 | Carbon black dispersion | For 10 different views: 9 in categories1 or 2 and 1 in category 3 | |||||||

8 | Oxidative induction time | (min) | ≥60 | ||||||

9 | 70℃ Low tempreture impact brittle property | Pass | |||||||

10 | Vapour permeability coefficient g.cm/(cm2·S·Pa) | ≤1.0×10-13 | |||||||

11 | Dimensional Stability | ±2.0 | |||||||

LDPE geomembrane liners are designed with features that ensure reliability and ease of use in diverse applications:

Provides 500% elongation at break (ASTM D6693), allowing 25% better conformity to irregular surfaces and subgrade movements than HDPE.

Offers 250 N puncture resistance (ASTM D4833) and 80 N tear resistance (ASTM D1004), reducing damage risks by 15% on uneven terrains.

Resists acids, alkalis, and salts, maintaining 95% integrity after EPA 9090 testing, suitable for moderate chemical exposure.

Functions at -70°C, ensuring 90% flexibility in cold climates, unlike PVC liners that stiffen below 0°C.

Supports thermal welding and adhesive bonding, achieving 97% seam strength, with prefabricated panels reducing field seams by 10%.

Contains 2% carbon black and UV stabilizers, ensuring 85% performance retention after 5–10 years of exposure.

Smooth liners ease cleaning, while textured liners with 1 mm asperities enhance 20% better slope stability for landfill caps.

These features make LDPE liners a practical choice for projects prioritizing flexibility and ease of installation.

LDPE geomembrane liners deliver significant advantages for cost-conscious and flexible containment projects:

These benefits position LDPE liners as an economical and adaptable solution for moderate-stress containment needs.

Yes, LDPE is a good geomembrane liner for many applications, particularly those where flexibility and conformability are key requirements. Its inherent flexibility allows it to adapt well to irregular subgrades and areas prone to settlement, reducing the risk of stress cracking. LDPE also offers good chemical resistance to a range of substances and provides a reliable barrier against leakage.

However, the “goodness” of LDPE as a geomembrane liner is application-dependent. While it excels in flexibility, it generally has lower tensile strength and puncture resistance compared to HDPE (High-Density Polyethylene). Therefore, for applications requiring high strength and puncture resistance, especially those involving sharp objects or significant mechanical stress, HDPE might be a more suitable choice. Factors to consider when evaluating LDPE as a geomembrane liner:

In conclusion, LDPE is a good geomembrane liner when its specific properties align with the requirements of the application. Its flexibility makes it ideal for many containment scenarios, but a thorough evaluation of the project needs is crucial for selecting the most appropriate material.

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) geomembrane liners serve similar containment purposes but differ in composition, performance, and application:

Recommendation: Choose HDPE for chemically aggressive, exposed, or high-strength projects like landfills; select LDPE for flexible, budget-conscious applications like ponds or canals.

LDPE geomembrane liners are versatile, addressing a range of containment needs in moderate-stress environments:

Used in fish and shrimp ponds, 20–40 mil liners prevent 98% water loss, boosting yields by 10% in regions like Malaysia.

Lines irrigation canals, decorative ponds, and rainwater collection systems, reducing seepage by 95% for water conservation.

Serves as temporary or secondary covers in municipal landfills, ensuring 98% leachate containment with 40-mil liners.

Contains neutral-pH effluents in agricultural or municipal lagoons, with 60-mil liners offering 95% chemical stability.

Used in canals and embankments, 30–40 mil liners prevent 90% of erosion on moderate slopes.

Supports manure or biogas storage, with 40-mil liners providing 97% impermeability for environmental protection.

Used in construction or spill containment, 20–30 mil liners offer 95% effectiveness for short-term projects.

These applications highlight LDPE’s suitability for flexible, cost-sensitive containment solutions.

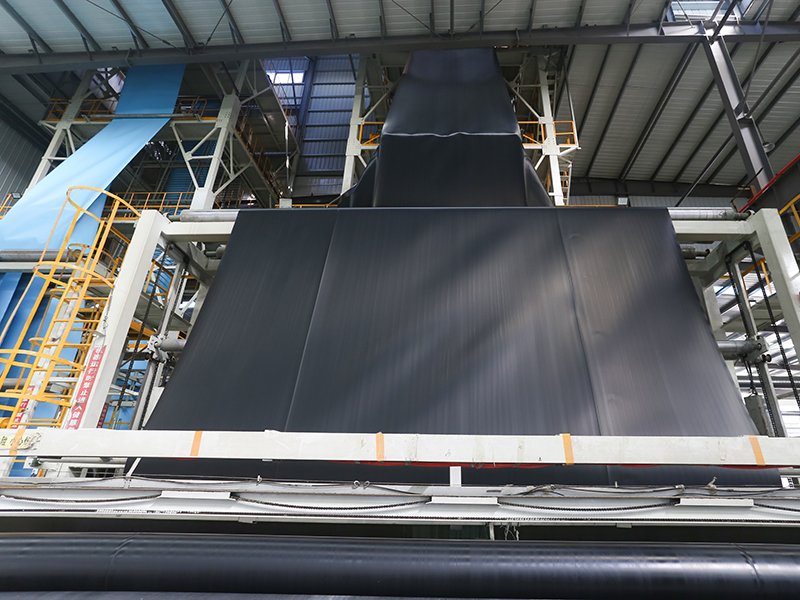

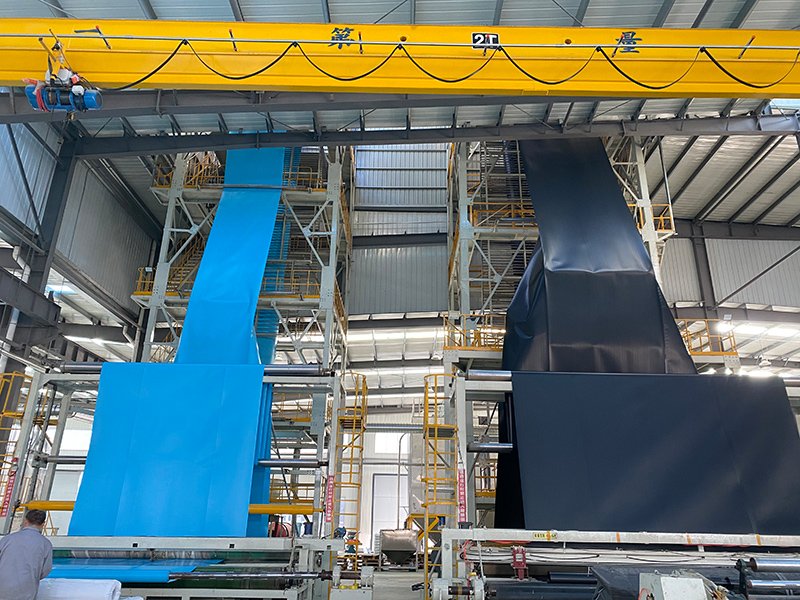

BPM Geosynthetics, as one of the largest geo liner manufacturers and companies in China, is renowned for strong geomembrane liners and geotextile liners manufacturing alibilities. We offer complete range of best quality geomembranes, geotextiles and related geosynthetic liners at competitive factory price for your environmental, civil engineering and mining applications.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbanes, geotextiles or other geosynthetic liner products or services, please fill in the form, we are always here repond to your inquiries as soon as possible.