Share:

The HDPE geomembrane liner, also known as geomembrane HDPE liner, is a high-performance, impermeable membrane engineered for containment applications in environmental, industrial, and civil engineering projects. Compared to PVC liners, HDPE liner excels in chemical resistance, UV stability, and large-scale affordability, making it ideal for demanding environments. Whether for mining, water conservation, or waste management, our HDPE liners ensure 99% containment efficiency and a 50+ year lifespan. Renowned for its durability, chemical resistance, and cost-effectiveness, this liner is a cornerstone in industries like mining, waste management, and water conservation.

As a leading geo liner manufacturers and companies, supplier and factory, BPM Geosynthetics offers HDPE geomembrane liners that meet ASTM D5199 and GRI GM13 standards, ensuring superior quality and compliance. Looking for Best HDPE geomembrane liner At Best Factory Price? BPM Geosynthetics Is The Trusted Geomembrane Manufacturer and Factory offering Best Solution.

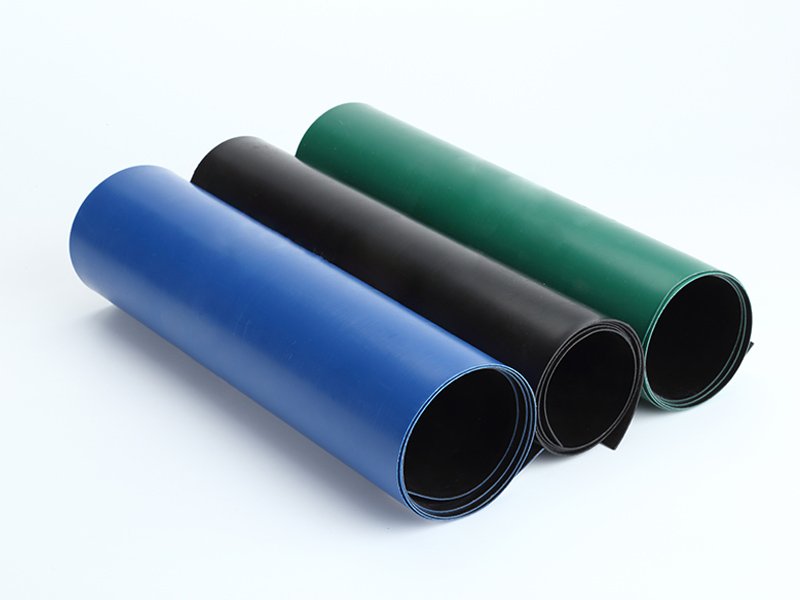

A High-Density Polyethylene (HDPE) geomembrane liner is a synthetic, impermeable membrane made from virgin polyethylene resin, designed to prevent fluid migration in containment systems. With a density of 0.94 g/cm³, HDPE liners offer exceptional tensile strength (27 N/mm at break, per ASTM D6693) and low permeability (≤10⁻¹³ cm/s), making them ideal for harsh environments. Available in smooth or textured finishes, these liners are thermally welded on-site to create seamless barriers, ensuring 99% containment efficiency. Geomembrane HDPE liners is made with 0.2~3mm in thickness and up to 10m in length, they are widely used in landfills, ponds, and mining operations, providing a robust solution for environmental protection and resource conservation, backed by a 50+ year lifespan when covered.

| Item | Detailed Item | Unit | Standard | Test frequency | GSO75 | GSO10 | GSO15 | GSO20 | GSO30 |

|---|---|---|---|---|---|---|---|---|---|

Mechanical Properties | Thickness | mm | ASMD5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

| Density | g/cc | ASMD1505/D792 | 90,000kg | 0.94 | |||||

| Tensile Properties | |||||||||

| Yield Strength | KN/m | ASMD6693 Type IV | 9,000 kg | 11 | 15 | 22 | 29 | 44 | |

| Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

| Yield Elongation | % | 13 | 13 | 13 | 13 | 13 | |||

| Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

| Tear Resistance | N | ASMD D1004 | 20,000kg | 93 | 125 | 187 | 249 | 374 | |

| Puncture Resistance | N | ASMD D4883 | 20,000kg | 240 | 320 | 540 | 660 | 960 | |

| Stress Crack Resistance | hr. | ASMD D5397 | per GRI GM-10 | 500 hr. | |||||

| Carbon black content | % | ASMD D4218 | 9,000kg | 2.0-3.0% | |||||

| Carbon black dispersion | ASMD D5596 | 20,000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

| Standard OIT | min | ASMD D3895 | 90,000kg | 100 min | |||||

| High pressure OIT | ASMD D5885 | 90,000kg | 500 min | ||||||

| Oven Aging at 85°C retained after 90 days | % | ASMD D5721 | per each formulation | 55% | |||||

| Standard OIT | ASMD D3895 | 80% | |||||||

| High pressure OIT | ASMD D5885 | 80% | |||||||

| UV Resistance | |||||||||

| High Pressure OIT – % retained after 1600 hrs | % | ASMD D5885 | per each formulation | 50% | |||||

Roll Size | Roll Width | m | 7 | 7 | 7 | 7 | 7 | ||

| Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

| Size stability | % | 2% | |||||||

HDPE geomembrane liners are available in various thicknesses to suit project requirements, typically ranging from 0.5 mm to 3.0 mm. Thickness is measured in millimeters (mm), mils (1 mil = 0.0254 mm), and microns (1 micron = 0.001 mm). Common thicknesses include:

Thicker liners (e.g., 80+ mils) offer 30% greater puncture resistance (356 N, ASTM D4833) and 50% longer service life, per GRI GM13 standards. Selection depends on subgrade conditions, hydrostatic pressure, and regulatory requirements.

HDPE geomembrane liners are 100% waterproof, providing reliable protection against liquid seepage. This feature is crucial for applications such as aquaculture ponds, landfills, and wastewater treatment facilities.

These liners exhibit high tensile strength, with a break strength of up to 28 MPa and an elongation at break of 700%. This makes them highly resistant to tearing and puncturing, ensuring long-term stability and durability.

HDPE geomembrane liners are resistant to a wide range of chemicals, including acids, alkalis, and salts. They can withstand corrosion from over 80 strong chemical media, making them suitable for use in harsh environments such as mining and chemical reaction tanks.

Thanks to the addition of carbon black, HDPE geomembrane liners possess good UV resistance. This prevents degradation when exposed to sunlight, extending the lifespan of the liner.

These liners can withstand extreme temperatures, making them suitable for use in various climatic conditions.

The materials used in HDPE geomembrane liners are non-toxic and environmentally friendly. They do not produce harmful substances during use, making them ideal for applications in aquaculture and drinking water ponds.

HDPE geomembrane liners offer excellent value for money. Their durability and longevity reduce the need for frequent replacements, resulting in significant cost savings over time.

These liners are lightweight and flexible, making them easy to install. They can be tailored to fit specific project requirements and can be laid over various substrates.

With a range of thickness options available, HDPE geomembrane liners can be selected to meet the specific needs of different projects.

The combination of high tensile strength, excellent chemical stability, and UV resistance ensures a long service life for HDPE geomembrane liners.

These benefits position HDPE liners as a top choice for sustainable containment solutions.

HDPE and PVC geomembrane liners serve similar containment purposes but differ significantly in composition, performance, and application:

Recommendation: Choose HDPE for chemical-intensive, exposed, or large-scale projects; opt for PVC for flexible, smaller-scale applications like MSW landfills.

HDPE geomembrane liners are versatile, serving critical roles across industries:

BPM Geosynthetics, as one of the largest geo liner manufacturers and companies in China, is renowned for strong geomembrane liners and geotextile liners manufacturing alibilities. We offer complete range of best quality geomembranes, geotextiles and related geosynthetic liners at competitive factory price for your environmental, civil engineering and mining applications.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbanes, geotextiles or other geosynthetic liner products or services, please fill in the form, we are always here repond to your inquiries as soon as possible.