When planning construction, soil reinforcement, or ground stabilization projects, geogrid is often the preferred material. When purchasing this product, the cost of geogrid is a significant factor in the procurement process. While a simple online search may yield several price ranges, the final cost depends on the complex interplay of materials, product specifications, and long-term value. As a leading manufacturer and supplier, BPM Geosynthetics understands that high-quality products are key to a successful project. While meeting stringent quality requirements, the BPM group also researches advanced product formulations that deliver performance while controlling costs. This guide provides a detailed analysis of the key factors determining geogrid pricing, helping you budget accurately, select suitable products, and choose the most cost-effective solution for your specific needs.

1. Core Factors That Drive Geogrid Pricing

1.1. Material and Polymer Quality Affects Geogrid Cost

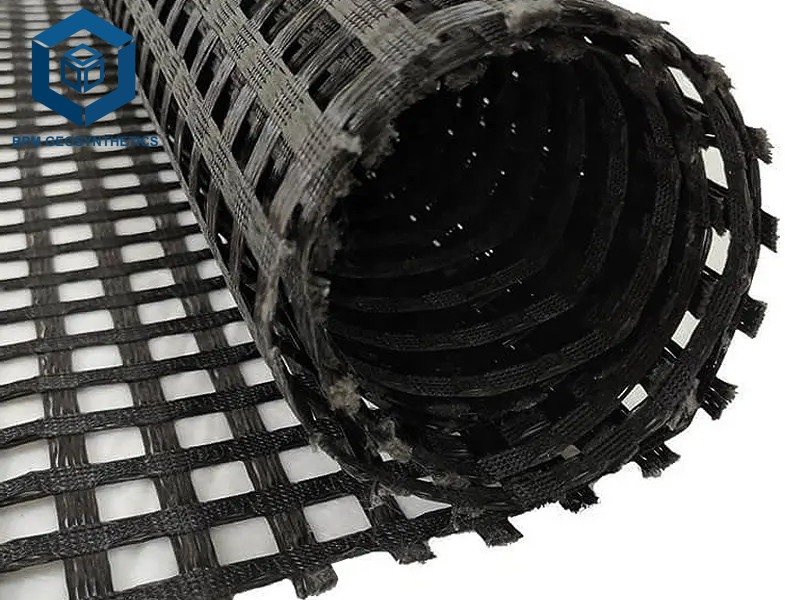

Geogrids are primarily made from polyester (PET), polypropylene (PP), high-density polyethylene (HDPE), or fiberglass, each with distinct properties. PET and oriented HDPE are common for high-strength, low-creep applications, but premium-grade polymers with enhanced UV stabilizers and additives for chemical resistance cost more. The quality of the polymer and the manufacturing process (e.g., uniaxial vs. biaxial orientation) directly impact tensile strength, junction efficiency, and long-term durability, making them critical price determinants.

1.2. Different Geometry and Specifications, Different Geogrid Cost

Key physical and mechanical properties significantly affect cost:

Tensile Strength and Modulus: The ultimate tensile strength (e.g., 20 kN/m, 80 kN/m, 150 kN/m) and stiffness are primary drivers. Higher strength and modulus grades require more advanced materials and processes, commanding a higher price.

Aperture Size and Shape: The geometry (square, rectangular, or triangular apertures) and dimensions (e.g., 25mm x 25mm, 40mm x 40mm) are engineered for specific soil interlock characteristics. Different designs involve varying material use and manufacturing complexity.

Roll Dimensions: Standard widths (e.g., 1m, 2m, 4m, 5.2m) and roll lengths affect production efficiency and logistics. Custom sizes may incur additional costs.

1.3. Project Scale and Order Quantity Affect Geogrid Cost

Suppliers like BPM Geosynthetics typically offer volume discounts. Ordering full container loads or large quantities for major infrastructure projects (e.g., highways, retaining walls) results in a lower unit cost compared to small orders for residential driveways or landscape walls.

1.4. Brand Reputation and Certifications

Established manufacturers invest in rigorous R&D, quality control, and independent third-party testing (e.g., against ISO, GRI, or specific national standards). This assurance of documented performance, consistency, and reliability often justifies a premium over lesser-known brands, reducing project risk.

2. Understanding the Total Cost of Ownership

2.1. Ancillary Materials and Accessories Affect System Cost

A complete geogrid reinforcement system involves more than just the geogrid roll. Total project cost must account for:

Connection Components: For some systems, connectors or specific seaming methods are needed to join rolls, affecting integrity.

Facing Elements: For retaining walls, the cost of concrete blocks, modular panels, or wrapped faces must be included.

Geotextiles: Often used as a separation layer behind wall facings or beneath the geogrid in subgrade stabilization to prevent soil mixing.

Backfill Material: The specification and cost of select fill material (often granular) are crucial, as its quality directly interacts with the geogrid to achieve design performance.

2.2. Installation and Labor Costs

Installation is a major variable. Key cost drivers include:

Terrain Complexity: Steep slopes or confined sites increase labor time and difficulty.

Site Accessibility: Affects equipment and material handling efficiency.

Labor Rates: Vary by region and contractor specialization.

Preparation Work: Subgrade preparation and compaction are critical and add to costs.

Professional installation following manufacturer specifications is vital. Reputable suppliers like BPM provide detailed installation guidelines, on-site technical support, or training, which can optimize processes, prevent errors, and control long-term costs.

2.3. Evaluating Long-Term Value and ROI

View geogrid as a long-term investment. A higher initial cost for a premium, certified product can lead to substantial savings by extending service life, reducing maintenance, minimizing differential settlement, and preventing costly repairs or failures. This lifecycle value often outweighs minor initial price differences.

3. Detailed Explanation of Geogrid Costs and Pricing Structure

3.1 Installation Cost Components

Geogrid installation costs are typically part of the earthworks or structural package and include:

Labor Costs: Unrolling, positioning, tensioning, cutting, and connecting geogrid layers. Crew rates vary by region and project complexity.

Equipment Costs: Standard earthmoving equipment (excavators, bulldozers) is used. For large walls, specialized equipment for handling heavy rolls may be needed.

Pricing Structure: Contractors may bid based on a rate per square meter of geogrid installed, a lump sum for the reinforcement package, or integrate it into the overall earthwork price. It’s advisable to request itemized quotes.

3.2 Key Elements for Efficiently Obtaining and Comparing Quotes

Provide suppliers/contractors with clear project details:

Technical Parameters: Required tensile strength (MD and XD if biaxial), aperture stability, roll width, and any specific polymer or coating needs.

Site Data: Soil reports, design drawings, cross-sections showing layer placement, and design software outputs (if available).

Construction Plans: Clearly indicate the area/length to be reinforced, layer spacing, and embedment details.

Comparison Techniques: Request a breakdown of material cost, delivery, and any technical support fees. Ask for project case studies with cost-benefit analyses. Prioritize suppliers who offer design review and technical validation.

4. Making a Cost-Effective Selection

4.1. Define Your Performance Requirements

Match the geogrid type to the application. A lightweight biaxial PP geogrid may suffice for base stabilization under a parking lot, while a high-strength uniaxial PET geogrid is essential for a steep mechanically stabilized earth (MSE) wall. Using an under-specified product risks failure; using an over-specified one wastes budget.

4.2. Compare Quotes with Full Transparency

Provide identical, detailed project specifications to all bidders. Request quotes that separate material, delivery, and support costs. Scrutinize the technical data sheets provided with each quote to ensure they meet the project’s engineered specifications.

4.3. Consider Supplier Partnerships

A reliable supplier like BPM Geosynthetics provides more than product. They offer certified test data, design software support, specification guidance, and warranty assurances. This technical partnership can prevent costly design oversights and ensure optimal, value-engineered solutions.

Conclusion

So, how much does geogrid cost? As explored, the answer integrates unit price, total system components, proper installation, and projected lifecycle value. The lowest-priced option per square meter may lead to higher total expenses through performance issues, complex installation, or premature failure. The most economical choice balances initial investment with proven, certified performance and durability. By partnering with a trusted manufacturer like BPM Geosynthetics, you gain access to the expertise needed to navigate these cost variables, ensuring your project achieves its engineering and financial goals efficiently. Focus on long-term value and total cost of ownership, not just the initial price tag, to make the smartest investment for your project’s success.