HDPE Liner (High-Density Polyethylene Liner) is a flexible, high-performance anti-seepage material celebrated for its exceptional impermeability, chemical stability, and durability. Its dense molecular structure effectively blocks water, acids, alkalis, and organic solvents, while its flexibility allows easy cutting, welding, and adaptation to irregular terrains. Boasting strong UV resistance and puncture resistance, it maintains a service life of 20–50 years under proper maintenance. Widely applied in environmental protection, water conservancy, agriculture, and mining projects, BPM Geosynthetics HDPE liners provide reliable containment for landfills, reservoirs, irrigation canals, and tailings ponds—an indispensable material for Russia’s infrastructure development amid its diverse climatic and geographical conditions, from Siberia’s frigid winters to its vast agricultural and industrial zones.

1. What is HDPE Liner Manufacturers?

HDPE Liner Manufacturers are companies specializing in producing high-performance, impermeable geomembranes from high-density polyethylene resin, catering to environmental, civil, and industrial containment needs such as landfills, mining, and water conservation. These manufacturers adhere to international standards (including ASTM and GRI) and Russian local standards (GOST) to ensure product quality, offering core features like chemical resistance, UV protection, and long-term durability. They also provide customization services for liner thickness (typically 0.5–3.0mm), size, and surface type (smooth or textured) to meet project-specific requirements. Reputable manufacturers hold authoritative certifications such as ISO 9001 (quality management) and ISO 14001 (environmental management), equipped with advanced production lines, strict quality control systems, and professional after-sales support—from technical consulting to on-site installation guidance.

2. How to Choose Right HDPE Liner Manufacturers?

2.1 Verify Qualifications and Certifications

Prioritize manufacturers with ISO 9001 and ISO 14001 certifications, and confirm compliance with Russian GOST standards and international ASTM/GRI norms. Ensure they hold valid production licenses and third-party test certifications (such as SGS or Intertek), as reputable firms maintain complete certification systems to guarantee standardized production.

2.2 Assess Product Adaptability to Russian Conditions

Focus on core performance indicators like low-temperature resistance (critical for Siberia’s -40℃ winters), penetration coefficient (≤1.0×10^-10cm/s for qualified products), and tensile strength. Reliable manufacturers’ products should withstand extreme climates and harsh industrial environments.

2.3 Evaluate Production and Supply Capacity

Investigate production scale, including factory area, number of professional lines, and annual output. Manufacturers with strong capacity ensure on-time delivery, avoiding delays in large-scale projects like national landfills or cross-region water conservancy initiatives.

2.4 Check Project Experience and Local Service

Prefer manufacturers with experience in Russian or cold-region projects, such as supplying liners for Arctic irrigation or Siberian mining sites. Review case records and confirm whether they offer localized technical support and installation guidance.

2.5 Confirm Customization and Cost-Effectiveness

Excellent manufacturers provide tailored solutions, such as adjusting thickness for frost resistance or optimizing width for large-area laying. Balance product quality with pricing to select cost-effective options suitable for project budgets.

3. The 6 Best HDPE Liner Manufacturers In Russia

3.1 Komitex GEO-HDPE Liner Manufacturers

Founded in 2005 and based in Syktyvkar, Komitex GEO is a leader in Russia’s geosynthetic industry. Part of the Komitex Group, it produces over 100 million square meters of geosynthetics annually, with HDPE liners available in 0.8–3.0mm thickness (smooth and textured variants). Complying with ISO 9001, GOST, and ASTM standards, its products excel in frost resistance (-40℃ tolerance), making them ideal for Siberian water conservancy and waste management projects. Serving domestic and CIS markets, it offers timely delivery and customized solutions, solidifying its reputation in large-scale infrastructure projects.

3.2 Kazan Petrochemical–HDPE Liner Manufacturers

Established in 1998 in Kazan, this manufacturer leverages Russia’s rich petrochemical resources to produce high-performance HDPE liners. Its flagship HDPE grade 15313-003 features exceptional low-temperature resistance and high rigidity, certified for food-grade applications (drinking water treatment, food processing). Adhering to ISO 9001, it provides third-party test reports for each batch, trusted in chemical storage and oilfield containment projects across Russia.

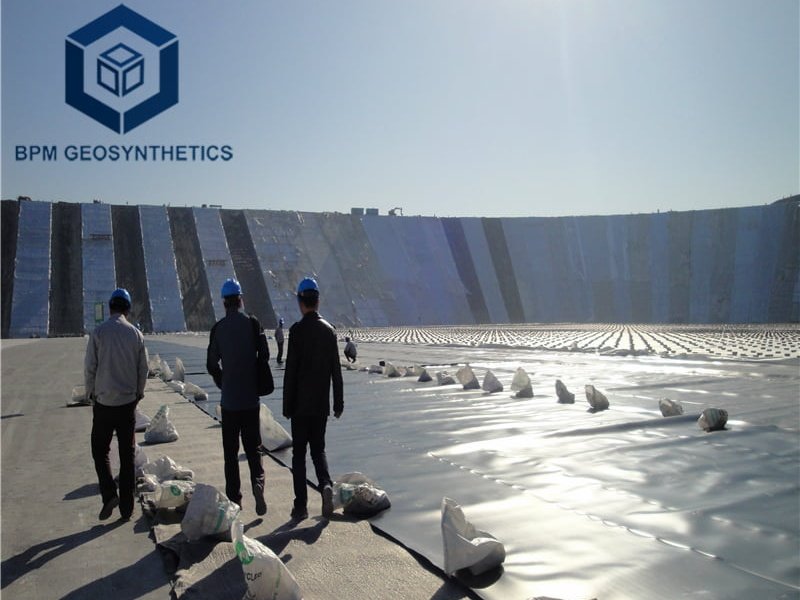

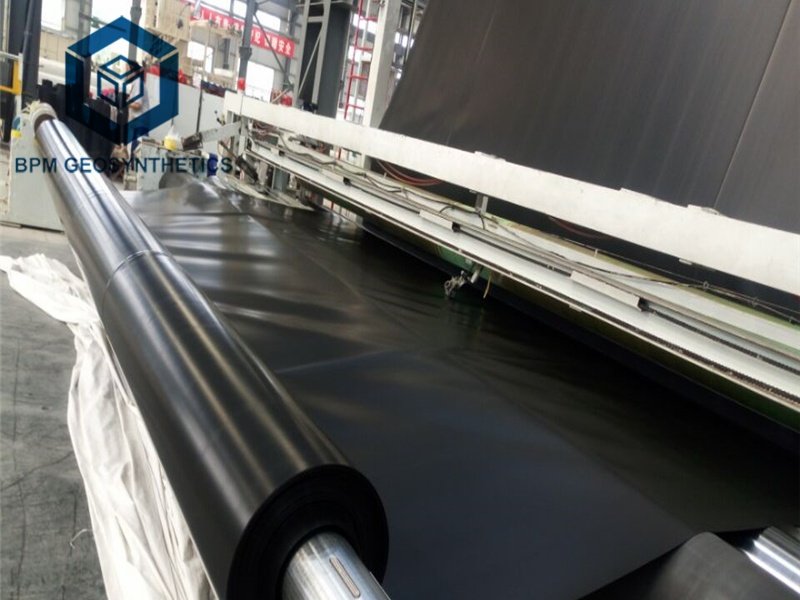

3.3 BPM Geosynthetics–HDPE Liner Manufacturers

A global leading geosynthetics manufacturer with a strong presence in Russia’s market, BPM Geosynthetics was founded in 2007 and is based in Taian, China. Operating a 36,000-square-meter ISO 9001, ISO 14001, and OHSAS 18001-certified facility, it employs over 160 professionals and exports to 81+ countries, including Russia . Its HDPE liners range in thickness from 0.2mm to 3.0mm with widths up to 10 meters, available in smooth and textured variants, and have passed SGS and Intertek tests . Tailored for Russia’s climate, the products offer excellent low-temperature flexibility and UV resistance, widely used in landfill containment, reservoir waterproofing, and mining projects. BPM provides one-stop solutions including OEM/ODM services and on-site installation guidance, with a 98% on-time delivery rate and 90% customer satisfaction .

3.4 TechnoNICOL–HDPE Liner Manufacturers

A renowned domestic brand with Moscow-based operations, TechnoNICOL specializes in cost-effective HDPE liners made from recycled raw materials without compromising performance. Its products feature strong puncture resistance and compatibility with geotextiles, widely used in road construction, landfills, and small-scale water conservancy. With a nationwide distribution network, it caters to both small contractors and large firms, emphasizing accessibility, practicality, and timely after-sales support.

3.5 Zapsibneftekhim (OOO Zapsibneftekhim)–HDPE Liner Manufacturers

Located in Tobolsk, this industry giant dominates Russia’s HDPE polymer supply, a key upstream provider for liner manufacturers. Accounting for 100% of Russia’s HDPE polymer exports in recent periods, its high-grade resins (e.g., HDPE 11503-070) deliver superior mechanical strength and oxidation resistance, forming the basis of premium HDPE liners. Partnering with downstream processors, it supplies materials for oil and gas pipelines, toxic waste disposal, and large-scale reservoir waterproofing, trusted for reliability in demanding applications.

3.6 Russgeosint LLC (OOO “Russgeosint”)–HDPE Liner Manufacturers

Based in Nizhny Novgorod, Russgeosint LLC combines HDPE liner production with professional installation services, offering end-to-end solutions. Specializing in environmental protection projects, its HDPE liners are engineered for landfills, reservoirs, and sludge dumps, using advanced thermal fusion welding technology to ensure leak-proof seams. The company’s experienced team provides on-site support from design to installation, addressing Russia’s complex terrain challenges, and its products meet strict geomembrane standards for long-term performance.

Summary

Russia’s HDPE liner market is supported by six leading manufacturers, each with distinct strengths aligned with the country’s infrastructure needs. Komitex GEO and Kazan Petrochemical lead in large-scale domestic projects with extreme climate adaptability; BPM Geosynthetics brings global expertise, high-quality products, and one-stop services to the Russian market; TechnoNICOL offers cost-effective solutions for civil and small-scale projects; Zapsibneftekhim underpins the industry with premium raw materials; and Russgeosint LLC excels in turnkey environmental project solutions. All manufacturers adhere to strict quality standards, ensuring their HDPE geomembrane meet the rigorous demands of Russia’s diverse geographical and climatic conditions. As the country’s construction and environmental protection sectors grow, these companies remain at the forefront of innovation, delivering reliable and durable anti-seepage solutions for critical infrastructure projects.