Geotextile membranes are essential geosynthetic materials widely used in civil engineering, environmental protection, and landscaping projects to provide soil stabilization, drainage, filtration, separation, and reinforcement. As global infrastructure investments are projected to reach USD 9.5 trillion by 2030, the demand for these versatile fabrics continues to surge, driving innovations in material science and manufacturing processes. According to the Polaris Market Research, the global geotextile market, valued at USD 7.91 billion in 2024, is expected to grow at a compound annual growth rate (CAGR) of 6.7% to reach USD 15.02 billion by 2034, with infrastructure projects accounting for 40% of demand, erosion control for 30%, and drainage systems for 20%.

For project managers, engineers, contractors, and procurement specialists, understanding geotextile membrane pricing is crucial for accurate budgeting and ensuring long-term project success. Prices in 2025 typically range from $0.15 to $5.00 per square foot ($1.61 to $53.82 per square meter), excluding installation and ancillary costs. This wide range reflects variations in material composition, manufacturing techniques, specifications, and project scale. Non-woven geotextiles, ideal for filtration and drainage, often fall at the lower end ($0.15–$2.50 per square meter), while high-strength woven variants for reinforcement command premiums up to $7.50 per square meter. Bulk orders can reduce costs by 10–30%, and certified products from reputable suppliers ensure compliance with standards like ASTM D4439 and ISO 9001, minimizing risks of failure that could escalate expenses by 20–50%.

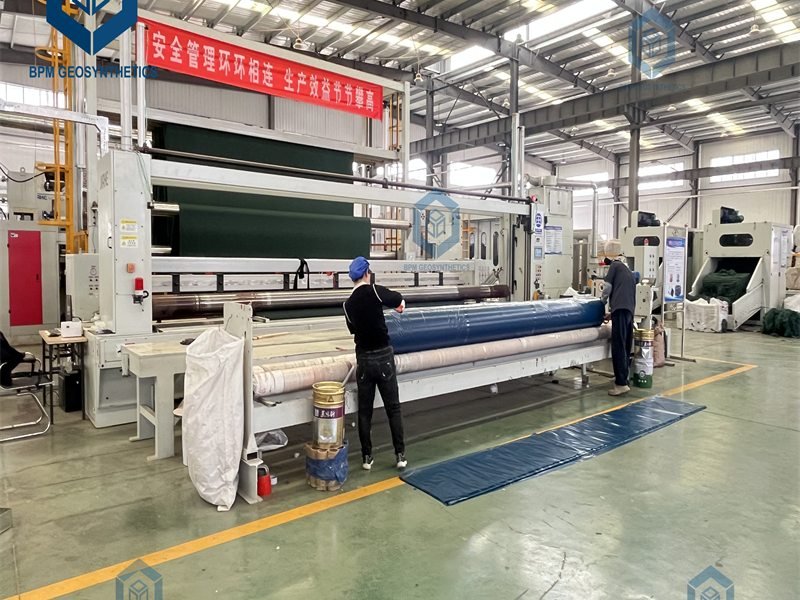

This ultimate guide delves into the intricacies of geotextile membrane pricing, drawing on 2025 market data from sources like BPM Geosynthetics, EarthShields, and Made-in-China.com. We explore types, specifications, cost factors, applications, calculation methods, installation tips, and supplier recommendations to equip you with actionable insights. By leveraging data-driven strategies, such as lifecycle cost analysis, you can optimize budgets while achieving up to 95% project reliability and reducing long-term maintenance by 15–30%. Whether you’re planning a highway subgrade, landfill liner, or residential driveway, this resource provides the depth needed for informed decision-making.

1.What Are Geotextile Membranes?

Geotextile membranes, often simply called geotextiles, are permeable synthetic fabrics engineered to interact with soil or other geotechnical materials. Fabricated primarily from polypropylene (PP), polyester (PET), or polyethylene (PE), these fabrics enhance soil performance by addressing challenges like erosion, poor drainage, and structural instability. Unlike impermeable geomembranes, geotextiles allow water passage while retaining soil particles, making them indispensable for sustainable construction practices.

2.Key Functions and Benefits for Geotextile Membranes

Geotextiles perform five primary functions, each backed by rigorous testing under standards like ASTM D4491 for hydraulic properties and ASTM D4632 for tensile strength:

- Separation: Prevents intermixing of dissimilar soil layers, such as soft subgrade and granular base materials. In road construction, this extends pavement life by 20–30% by reducing rutting.

- Filtration: Permits water flow while blocking fine particles, essential for drainage systems. Permeability coefficients range from 10⁻¹ to 10⁻⁴ cm/s, retaining 95% of soil fines in applications like French drains.

- Drainage: Channels excess water laterally or vertically, reducing hydrostatic pressure by up to 50% in retaining walls and embankments.

- Reinforcement: Increases soil tensile strength by 20–40%, allowing steeper slopes (up to 1:1 ratios) and reducing aggregate needs by 15% in base courses.

- Protection: Cushions sensitive liners like HDPE geomembranes in landfills, preventing punctures and extending service life by 25%.

Benefits extend beyond functionality: geotextiles reduce overall project costs by 10–20% compared to traditional methods, per ASTM D4439, by minimizing material usage and excavation. Environmentally, they promote soil conservation, cutting erosion by 60% in coastal and riverbank applications. With lifespans of 20–50 years under burial (UV-stabilized variants last 5–10 years exposed), they offer a high return on investment, especially in regions with stringent regulations like the EU’s Water Framework Directive.

3.Historical Context and Market Evolution for Geotextile Membranes

Introduced in the 1960s as substitutes for granular filters, geotextiles have evolved from basic woven PP fabrics to advanced composites integrating geogrids and sensors. The 2025 market reflects this maturity, with Asia-Pacific (led by China) holding 45% share due to manufacturing scale, while North America emphasizes eco-friendly variants like biodegradable coir (lasting 3–5 years). Innovations such as smart geotextiles with embedded moisture sensors add 20–50% to costs but reduce monitoring expenses by 15% in long-term projects.

In summary, geotextile membranes are not mere fabrics but engineered solutions that integrate seamlessly into geotechnical systems, delivering measurable performance metrics like 50% enhanced load-bearing capacity and 95% filtration efficiency.

4.Types of Geotextile Membranes

Geotextile membranes are classified by manufacturing method, material, and structure, each tailored to specific performance needs. The three primary types—woven, non-woven, and knitted—account for 90% of the market, with woven and non-woven dominating at 40% and 50% shares, respectively. Selection hinges on project demands: woven for high-load reinforcement, non-woven for hydraulic functions.

4.1Woven Geotextiles

Produced by interlacing monofilament, multifilament, or slit-film tapes on a loom, woven geotextiles offer superior tensile strength (50–150 kN/m) and low elongation (<10%), ideal for structural applications. They exhibit moderate permeability (50–100 gpm/ft²) but excel in soil confinement.

- Specifications:

- Aperture Size: 0.1–0.5 mm (per ASTM D4751), ensuring 80–90% soil retention.

- Roll Dimensions: Widths 4.5–6 m, lengths 50–100 m; weight 200–800 g/m².

- Durability: 50+ years buried; UV resistance up to 500 hours (AATCC 16A).

- Applications:

- Road bases and embankments: Reduces base thickness by 15–20%, saving $50,000–$150,000 on 10,000 m² projects.

- Retaining walls: Enhances stability by 30%, per AASHTO M288.

- Coastal protection: Armors dunes against storm surges, retaining 95% sediment.

- Pricing (2025): $0.30–$3.00 per square foot ($3.23–$32.29/m²), with high-tenacity PET variants at the upper end. Bulk discounts: 15–25% for >10,000 m².

Examples include Terram T1000 (20 kN/m tensile, $1.50/m²) for highway reinforcement and Shandong Dexuda woven PP ($0.50/m²) for temporary access roads.

4.2Non-Woven Geotextiles

Formed by needle-punching or heat-bonding staple fibers into a random web, non-woven geotextiles prioritize high permeability (100–200 gpm/ft²) and filtration efficiency (95% retention of 0.1 mm particles). They offer moderate strength (5–50 kN/m) and are 20–30% cheaper than woven due to simpler production.

- Specifications:

- Thickness: 0.5–3.0 mm; elongation 40–100% for flexibility.

- Puncture Resistance: 200–800 N (ASTM D4833), ideal for cushioning.

- Chemical Resistance: pH 2–13, inert to most soils.

- Applications:

- Drainage trenches: Filters fines in 65% of stormwater systems, reducing clogging by 70%.

- Landfill liners: Protects geomembranes, preventing 95% of punctures.

- Landscaping: Weed suppression in patios, with 50-year durability.

- Pricing (2025): $0.15–$1.50 per square foot ($1.61–$16.15/m²), lightweight (100–200 g/m²) at $0.15–$0.50. Heavier options (300–800 g/m²) add $0.50–$1.00.

Popular products: Pro Fabric Supply 8 oz needle-punched ($0.80/m²) for erosion control and BPM non-woven PP ($0.20/m²) for garden paths.

5.Knitted and Specialty Geotextiles

Knitted geotextiles, interlooped yarns for balanced strength (20–80 kN/m), are niche (5% market share) for flexible applications like geosynthetic clay liners. Specialty types include composites (geotextile + geogrid, $2.00–$5.00/ft²) and biodegradable coir ($0.10–$1.00/m², 3–5 year life).

- Specifications: High elongation (50–100%); integrated sensors in smart variants for real-time monitoring.

- Applications: Bioengineering slopes; temporary erosion control in agriculture.

- Pricing: $0.50–$2.00 per square foot, with eco-options 10–20% premium for sustainability certifications.

Type | Tensile Strength (kN/m) | Permeability (gpm/ft²) | Typical Cost ($/m²) | Key Application |

Woven | 50–150 | 50–100 | 3.23–32.29 | Reinforcement (Roads) |

Non-Woven | 5–50 | 100–200 | 1.61–16.15 | Filtration (Drainage) |

Knitted/Specialty | 20–80 | 80–150 | 5.38–21.53 | Flexible Protection |

This classification ensures alignment with project specs, where mismatched types can increase failure rates by 15–25%.

6.Key Specifications and Parameters for Geotextile Membranes

Selecting the right geotextile requires evaluating parameters that dictate performance and cost. These are standardized by ASTM, ISO, and AASHTO to ensure interoperability.

6.1Mechanical Properties

- Tensile Strength: Measures load-bearing capacity; minimum 8 kN/m for separation (ASTM D4595). Woven types exceed 100 kN/m for heavy reinforcement, correlating to 20% higher costs.

- Elongation at Break: 10–50% for woven (low stretch) vs. 50–100% for non-woven (flexible). High elongation suits seismic zones, adding 5–10% premium.

- Puncture Resistance: 150–500 N; critical for protection layers, where 300 N variants reduce repair costs by 20%.

6.2Hydraulic Properties

- Permeability/Water Flow Rate: 50–300 gpm/ft² (ASTM D4491); non-woven excels here, essential for 70% of drainage projects.

- AOS (Apparent Opening Size): 0.05–2.0 mm; finer AOS (0.1 mm) for silt retention, increasing price by 15%.

6.3.Durability and Environmental Resistance for Geotextile Membranes

- GSM (Grams per Square Meter): 100–800 g/m²; 200 g/m² standard for roads ($0.50/m²), 500 g/m² for landfills ($1.50/m²).

- UV Resistance: 100–500 hours exposure; stabilized PP adds $0.10–$0.30/m².

- Chemical Resistance: Inert to pH 2–13; PET for alkaline soils, 20% costlier than PP.

6.4.Testing and Certification

Compliance with GRI-GS8 (endurance) ensures 50-year design life. Parameters like CBR puncture (ASTM D6241) guide selection: 1,500 lbs for heavy-duty, inflating costs by 25%.

These specs directly influence pricing: a 300 g/m² non-woven with 150 kN/m strength costs 30–50% more than basic 100 g/m² but yields 40% better ROI via reduced maintenance.

7.Factors Influencing Geotextile Membrane Pricing

Geotextile prices fluctuate 10–20% annually due to raw material volatility and supply chain dynamics. In 2025, PP resin prices ($1.20–$1.50/kg) drive 60% of costs, with polyester at $2.00–$2.50/kg. Key factors include:

7.1.Material Composition for Geotextile Membranes

PP dominates (60% market) at $0.20–$2.00/m² for cost-effectiveness and 95% chemical resistance. PET ($0.75–$2.50/m²) offers 20% better UV stability but hydrolyzes in alkaline soils. Recycled variants save 15–25% but may compromise strength by 10%.

7.2.Manufacturing Type and Process for Geotextile Membranes

Non-woven (needle-punching) is 20% cheaper ($0.20–$2.50/m²) than woven (loom weaving, $0.50–$3.00/m²) due to automation. Heat-bonded non-woven adds $0.10/m² for uniformity.

7.3.Weight and Thickness

Higher GSM (300–500 g/m²) increases durability but raises costs 50–100% ($1.00–$5.40/m²). Thickness (1–3 mm) correlates: 2 mm adds 20% for puncture resistance.

7.4Project Scale and Volume

Economies of scale: >10,000 m² yields 10–30% discounts. Small orders (<1,000 m²) incur 15% premiums for setup.

7.5Additives and Certifications

UV stabilizers or flame retardants add 5–15% ($0.05–$0.50/m²). ISO 9001/ASTM certification premiums 10–15% but cuts liability by 20%.

7.6Geographic and Market Variations

Asia: $0.15–$3.00/m² (China dominance). Europe: $0.50–$7.50/m² (strict regs). U.S.: $0.30–$5.00/m², influenced by logistics ($0.05–$0.20/m² shipping).

Factor | Impact on Cost | Example Savings Strategy |

Material (PP vs. PET) | +20% for PET | Use PP for non-alkaline sites |

GSM (100 vs. 500) | +50–100% | Match to load; test soil |

Volume (>10k m²) | -10–30% | Consolidate projects |

Certification | +10–15% | Prioritize for public bids |

Geopolitical factors, like 5% shipping hikes from tensions, underscore the need for local sourcing.

8.Current Market Price Ranges for Geotextile Membranes

2025 pricing reflects stabilized supply chains post-2024 fluctuations, with averages $0.20–$3.00/m² globally. Data from BPM and EarthShields:

- Non-Woven: $0.15–$5.40/m² (lightweight $0.15–$0.50; heavy $1.00–$5.40).

- Woven: $0.30–$7.50/m² (standard $0.30–$0.70; high-strength $3.00+).

- Specialty (e.g., Tubes): $5.40–$54.00/m², for dewatering bags.

Regional Breakdown:

- China: $0.14–$1.25/m² (Made-in-China listings).

- S.: $0.15–$0.70/ft² ($1.61–$7.53/m²).

- Europe: $0.50–$2.50/m².

Bulk: 20% off for 100,000 m². Trends: Sustainable coir up 10%, smart fabrics +50%.

9.How to Calculate Geotextile Membrane Costs for Your Project

Accurate costing integrates material, installation, and lifecycle expenses. Follow this step-by-step methodology:

- Determine Area: Measure project footprint (L × W). For slopes/ponds: Add 10–20% for contours (e.g., pond: [L + 2×Depth +5′] × [W + 2×Depth +5′]).

- Select Specs: Match type/GSM to needs (e.g., 200 g/m² woven for roads).

- Material Cost: Area × Unit Price + 10% Waste. Example: 5,000 m² × $0.50/m² = $2,500 + $250 waste = $2,750.

- Installation: $0.50–$2.00/m² labor + $0.20–$1.00/m² prep. Total: 30–50% of material.

- Ancillary: Geotextile underlay $0.15–$0.50/m²; anchors $0.05–$0.15/m².

- Lifecycle: Divide total by lifespan (20–50 years). Factor 15% maintenance savings.

Example: 10,000 m² Road Project

- Material: $0.50/m² woven = $5,000

- Installation: $1.00/m² = $10,000

- Prep/Shipping: $3,000

- Total: $18,000 ($1.80/m²); ROI: 25% via 15% aggregate savings.

Tools like BPM’s calculators refine estimates, factoring 5–10% contingencies.

10.Installation Methods and Costs

Installation comprises 30–50% of total costs ($0.50–$2.00/m²), demanding precision to avoid 15% failure rates from overlaps or punctures.

10.1Step-by-Step Installation Guide

- Site Preparation: Clear debris, grade to <1% slope ($0.20–$1.00/ft²). Compact to 95% Proctor.

- Unrolling: Perpendicular to drainage; 300–600 mm overlaps, sewn/stapled for slopes.

- Securing: Pins every 1–2 m ($0.01–$0.03 each); sandbags for wind.

- Backfilling: 150–300 mm cover in 150 mm lifts, compacted to 90%.

- Quality Control: Destructive seam tests (ASTM D4885); 95% pass rate.

Costs: Labor $0.30–$1.00/m²; equipment $0.10–$0.50/m². Slopes add 20%.

10.2Tips for Cost-Effective Installation

- Use GPS-guided rollers for 20% efficiency gains.

- Train crews: Reduces errors by 15%, per GRI-GS19.

- Overlap Optimization: 12–18 inches saves 10% material.

- Phased Rolling: Minimizes wrinkles (20% effectiveness loss).

For a 1,000 m² driveway: $600 labor + $300 prep = $900 total install.

11.Choosing the Right Geotextile Membrane for Your Project

Align selection with site analysis: Soil type (sandy: non-woven filtration; clay: woven reinforcement), load (CBR >20: high GSM), and hydrology (high flow: >100 gpm/ft²).

- Assess Requirements: Use AASHTO M288 for roads; GRI-GS8 for landfills.

- Prioritize Quality: Certified products (10–15% premium) yield 20% lifecycle savings.

- Evaluate Suppliers: Compare BPM (bulk discounts) vs. Terram (premium certs).

- Long-Term Costs: Factor 15–25% savings from recycled/durable options.

Case: Highway project with Terram T1000 saved $150,000 via 15% thinner base.

12.Industry Trends Affecting Geotextile Membrane Costs in 2025

- Sustainability: Biodegradable coir/jute ($1.00–$5.00/ft²) up 10%, driven by ESG mandates; saves removal costs ($1,000/acre).

- Smart Integration: Sensor-embedded fabrics (+$2.00–$10.00/ft²) cut monitoring by 15%.

- Raw Material Fluctuations: PP up 5% from energy prices; hedge via long-term contracts.

- Global Variations: Asia exports down 5% due to tariffs, boosting local U.S./EU pricing 3–7%.

Market growth: 6.5% CAGR, with composites rising 20%.

13.Top Suppliers and Recommendations

Leading 2025 suppliers:

- BPM Geosynthetics: $0.15–$3.00/m²; full range, ISO-certified; best for bulk Asia exports.

- EarthShields: $0.15–$5.00/ft²; U.S.-focused, 20+ years; excels in custom non-woven.

- Terram/TCS Geotechnics: $0.50–$2.50/m²; premium European quality for high-spec projects.

- Shandong Dexuda: $0.15–$3.00/m²; cost-leader for woven, 10–20% discounts.

- Pro Fabric Supply: $0.80–$2.00/m²; needle-punched specialists, fast U.S. shipping.

Request quotes from 3–5 for 10–15% negotiation leverage. BPM offers tailored guidance for 95% success.

14.Cost-Saving Strategies

- Bulk and Local Sourcing: 20–30% off; consolidate to cut shipping 15%.

- Lifecycle Analysis: Prioritize 50-year fabrics; amortize over 20 years saves 25%.

- Hybrid Designs: Combine with geogrids for 10–15% material reduction.

- Testing Early: Soil borings ($500–$2,000) prevent 20% over-spec purchases.

15.Conclusion

BPM Geotextile membrane prices in 2025, ranging $0.15–$5.00 per square foot, are shaped by type, specs, and scale, but strategic selection unlocks 10–30% savings and superior performance. From woven reinforcement at $0.30–$3.00/ft² to non-woven filtration at $0.15–$1.50/ft², these fabrics deliver 20–40% soil enhancement and 50% erosion reduction, per ASTM standards. By calculating total costs (material + 30–50% install), aligning with project needs, and partnering with certified suppliers, you ensure durable, compliant outcomes.

For competitive quotes and expert advice, contact The Best Project Material Co., Ltd (BPM Geosynthetics) today. Our ISO-certified products and global delivery optimize your budget while guaranteeing reliability.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.