In the field of waste management and environmental protection, selecting high-quality HDPE geomembrane liner is crucial. High-quality HDPE geomembrane liners serve as robust barriers against contaminants, effectively protecting soil and groundwater. They must possess a range of critical characteristics to ensure long-term reliability and performance. These characteristics include exceptional waterproofing performance to prevent leaks, superior chemical resistance to withstand corrosive substances, and excellent UV stability to ensure durability in outdoor environments. Additionally, HDPE geomembrane liner should be easy to install, have high seam strength, and be adaptable to various terrains and environmental conditions. By carefully evaluating these key attributes, you can select a high-density polyethylene HDPE geomembrane liner that meets the specific requirements of your project, while minimizing environmental impact and maximizing cost-effectiveness.

As China’s largest professional manufacturer and exporter of HDPE geomembrane liner, BPM Geosynthetics Company can provide valuable information on how to select HDPE geomembrane liner correctly.

1. Material Properties of HDPE Geomembrane Liner

The purity and molecular weight distribution of high-density polyethylene significantly impact the performance of HDPE geomembrane liner. High-purity HDPE offers excellent chemical stability and impermeability. This effectively prevents the penetration of harmful substances, thereby extending the service life of HDPE geomembrane liner.

1.1 HDPE Geomembrane Liner Permeability Resistance

The permeability coefficient is a key indicator of a HDPE geomembrane liner’s waterproofing performance. A low permeability coefficient (e.g., <10⁻¹² cm/s) indicates superior waterproofing effectiveness. The dense molecular structure of high-density polymers forms a barrier that completely blocks the migration of liquids (e.g., leachate) and gases (e.g., methane).

1.2 Chemical Stability

The geomembrane’s resistance to various chemical substances is critical. HDPE geomembrane liner can withstand acidic and alkaline environments with a pH range of 1–14. They resist corrosion from over 300 chemical substances, including petroleum hydrocarbons and heavy metal ions. In mine tailings ponds, they maintain structural integrity even after prolonged exposure to sulfates at concentrations as high as 5,000 mg/L. They must possess acid resistance, alkali resistance, and resistance to organic solvents to adapt to diverse chemical environments.

2. HDPE Geomembrane Liner Physical Properties

2.1 Geomembrane Mechanical Strength

The tensile strength and tear strength of HDPE geomembrane liner determine their durability during installation and use. In complex terrain or environments subject to external forces, high mechanical strength prevents material rupture, ensuring the integrity of the waterproofing system.

2.2 Elongation

The elongation of HDPE geomembrane liner affects their ability to adapt to terrain changes and meet stretching requirements during construction. A high elongation rate (e.g., >700%) enables it to better conform to irregular surfaces, reduce stress concentration caused by terrain changes, and improve construction efficiency.

2.3 Abrasion Resistance

The abrasion resistance of HDPE geomembrane liners determines their service life during long-term use. In scenarios involving particle friction or frequent mechanical activity, good abrasion resistance reduces material wear and lowers maintenance costs.

3. HDPE Geomembrane Liner Environmental Adaptability

UV Stability: The UV stability of HDPE geomembrane liner determines its service life in outdoor environments. With the addition of specific UV stabilizers, HDPE geomembranes can maintain stable performance when exposed to sunlight for long periods of time. This makes them suitable for outdoor applications such as waste liquid ponds and landfills.

4. HDPE Geomembrane Liner Construction and Installation

4.1 Welding Performance

The welding quality of HDPE geomembrane liner is critical to the integrity of the overall waterproofing system. Welding strength should meet or exceed the strength of the base material. The simplicity and reliability of the welding process can enhance construction efficiency and quality control.

4.2 Ease of Installation

The size, weight, and flexibility of HDPE geomembrane liner influence the installation process. Larger HDPE geomembrane liner reduce the number of seams, accelerating construction speed. Good flexibility facilitates installation on complex terrain.

4.3 Compatibility

The compatibility of HDPE geomembrane liner with other construction materials (such as geotextiles, concrete, etc.) is critical. In composite waterproofing systems, materials must work together effectively to form a reliable waterproof barrier.

5.HDPE Geomembrane Liner Environment and Sustainability

Environmental Performance: The environmental impact of HDPE geomembrane liner during production and use must be strictly controlled. They should not contain harmful substances and should be recyclable to meet increasingly stringent environmental requirements.

Contribution to Sustainable Development: HDPE geomembrane liner contribute to environmental protection and sustainable development by reducing leakage and protecting soil and groundwater. For example, they prevent harmful substances from seeping into soil and groundwater in landfills, thereby protecting the ecological environment.

6.HDPE Geomembrane Liner Cost and Benefits

6.1 Initial Investment Costs

There are significant price differences between HDPE geomembrane liner of different qualities. By selecting cost-effective products that meet performance requirements, project budgets can be effectively controlled.

6.2 Long-Term Maintenance Costs

The service life, UV resistance, and damage resistance of HDPE geomembrane liner influence their long-term maintenance costs. High-quality HDPE geomembrane liner reduces the frequency of repairs and replacements, thereby lowering long-term costs.

6.3 Comprehensive Benefits

The value of HDPE geomembrane liner should be comprehensively assessed from multiple perspectives, including environmental, social, and economic benefits. Effective waterproofing measures can reduce environmental pollution risks, avoid environmental remediation costs and legal liabilities caused by leaks, and bring long-term comprehensive benefits to businesses and society.

7. HDPE Geomembrane Liner Application Scenarios and Customization

Different Application Scenarios: Different application scenarios have varying requirements for HDPE geomembrane liner. For example, landfills prioritize waterproofing and chemical stability, while tailings ponds in mines demand higher abrasion resistance and corrosion resistance.

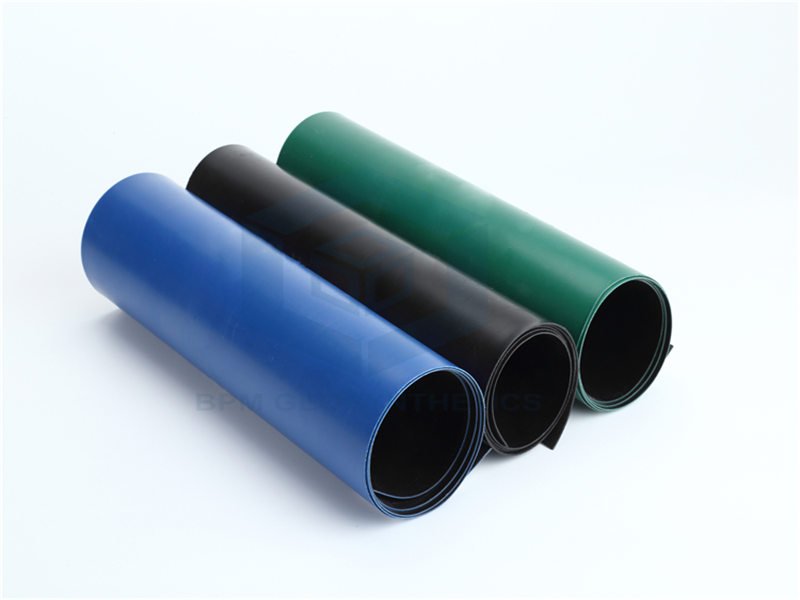

Customization Capabilities: HDPE geomembrane liner manufacturers should provide customized products based on customers’ specific needs. Customizing thickness, dimensions, color, or adding specific additives can meet special environmental or functional requirements, enhancing the product’s applicability and competitiveness.

Conclusion

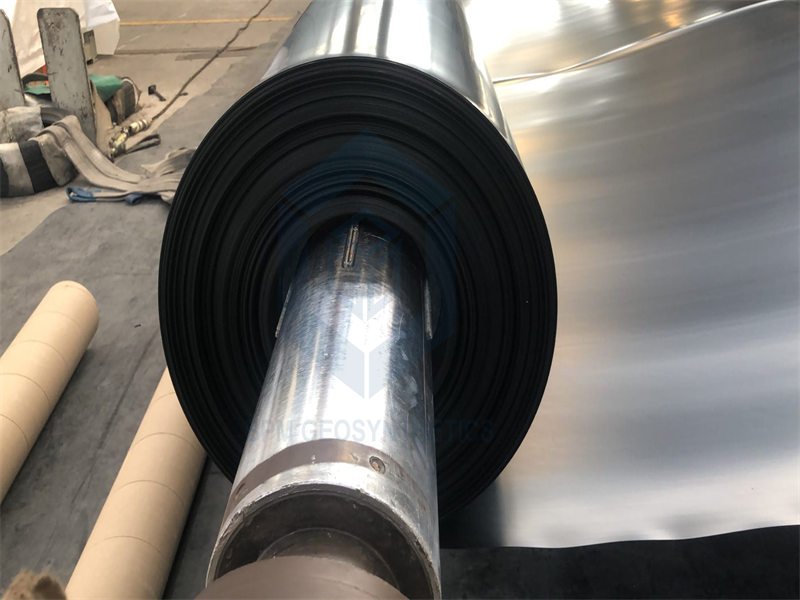

In different application environments, consider the different characteristics of HDPE geomembrane liner to select the appropriate one. HDPE geomembrane liner of different thicknesses and colors have distinct properties, which can affect their service life and resistance to aging, thereby impacting the performance of each project. Among these factors, the material properties and physical characteristics of HDPE geomembrane liner are critical considerations. BPM geosynthetics Company can produce HDPE geomembrane liner ranging from 0.2 to 3 millimeters in thickness, including three materials: HDPE, LDPE, and LLDPE. We can provide solutions for various projects, such as landfills, fish and shrimp ponds, dams, canals, artificial lakes, reservoirs, and mining projects. BPM Geosynthetics company has state-of-the-art geomembrane production lines in China, ensuring product quality. If you have any questions regarding geomembrane products or construction issues, please feel free to contact BPM Company for assistance.