Share:

PET woven geotextile is designed and manufactured geo liner with unparalleled tensile strength, superior creep resistance, and exceptional long-term durability for the most demanding civil engineering applications. Its unique combination of properties makes it the material of choice for projects where structural integrity, long-term stability under heavy loads, and reliable performance in challenging environments are paramount. While also providing effective separation and filtration capabilities, the primary advantage of PET Woven Geotextile lies in its ability to provide robust and reliable reinforcement for critical infrastructure, ensuring safety, longevity, and optimal performance. For engineers and contractors prioritizing ultimate strength and enduring reliability, PET Woven Geotextile provides a solid foundation for the most critical and challenging geotechnical projects.

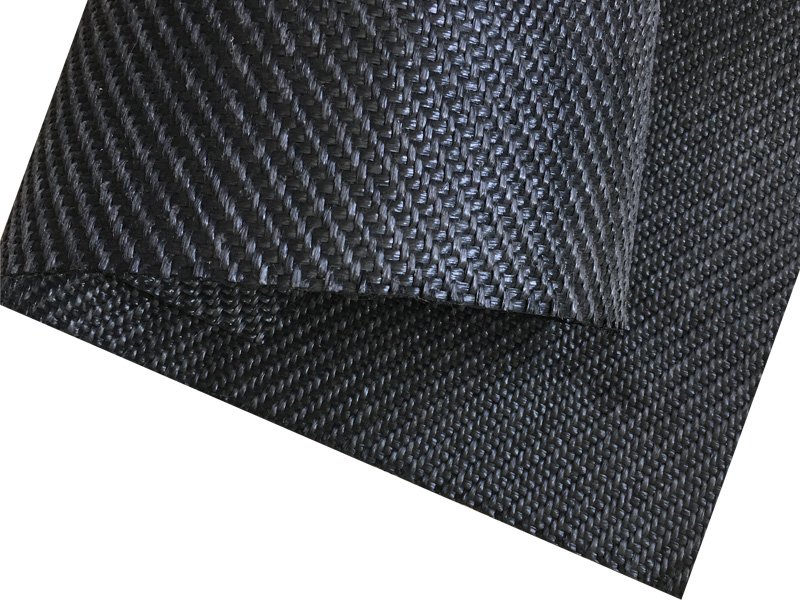

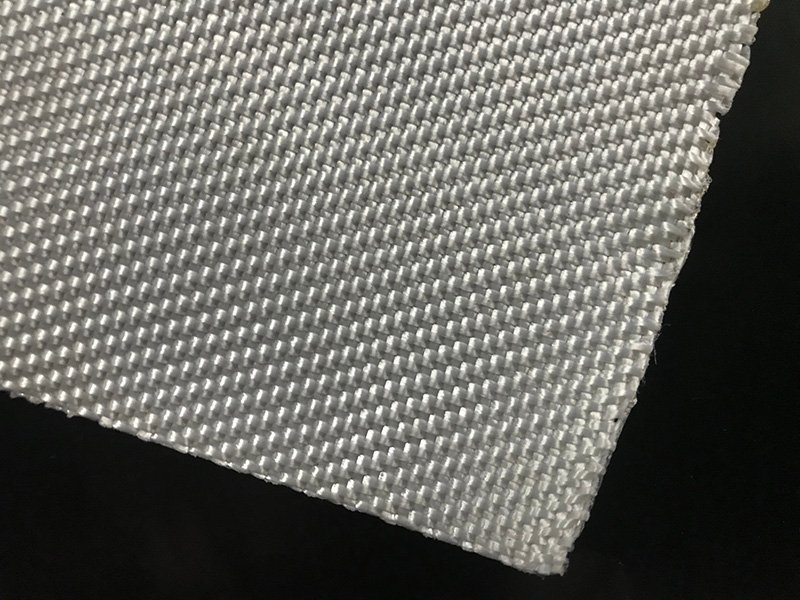

A PET woven geotextile is a high-performance, permeable geotextile fabric precisely engineered from high-tenacity polyester (PET) yarns that are interwoven in a structured and consistent pattern. This meticulous weaving process creates a dimensionally stable geotextile characterized by exceptional tensile strength in both the machine (warp) and cross-machine (weft) directions. What distinguishes PET woven geotextile is the inherent properties of polyester, which offers significant advantages over polypropylene (PP), particularly in terms of creep resistance and long-term durability under high, sustained loads. Polyester also exhibits superior resistance to certain chemical environments, especially acidic conditions, and possesses a higher resistance to degradation from ultraviolet (UV) radiation compared to standard PP. The controlled weaving process also results in a defined pore structure, allowing for engineered filtration and separation capabilities alongside its primary function of reinforcement.

The principal role of a PET woven geotextile is to provide robust and reliable reinforcement to soil structures in critical civil engineering applications. Its superior tensile strength and minimal creep deformation under load make it ideally suited for projects involving significant and sustained stresses, such as the construction of reinforced soil retaining walls, the stabilization of steep slopes, the reinforcement of embankments over soft foundations, and the enhancement of bearing capacity for heavy loads. While also functioning as an effective separator between dissimilar materials and contributing to filtration in drainage systems, the primary selection criterion for PET woven geotextile often centers on its unmatched strength and long-term performance characteristics in demanding geotechnical environments. Leading geosynthetic manufacturers produce a diverse range of PET woven geotextile products, each engineered to meet specific strength, stiffness, and filtration requirements. Utilizing advanced weaving technologies and adhering to stringent quality control standards, these manufacturers ensure the consistent production of high-performance PET woven geotextile that meets or exceeds rigorous industry specifications and regulatory guidelines.

| Property | Unit | BPM100-50 | BPM300-50 | BPM500-50 | BPM600-50 | BPM1200-50 |

|---|---|---|---|---|---|---|

| Ultimate Tensile Strength MD | KN/m | 100 | 300 | 500 | 600 | 1200 |

| Ultimate Tensile Strength CD | KN/m | 50 | 50 | 50 | 50 | 50 |

| Strain at short term strength | % | 10 | 12 | 12 | 12 | 12 |

| Elongation | % | 30 | 30 | 30 | 30 | 30 |

| Apparent Opening Size | mm | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| UV resistance ( Retained 500 Hours) | % | 70 | 70 | 70 | 70 | 70 |

| Width | m | 5.2 | 5.2 | 5.2 | 5.2 | 5.2 |

| Height | m | 100 | 100 | 100 | 100 | 75 |

| Roll weight | Kg | 140 | 320 | 480 | 580 | 810 |

PET Woven Geotextile possesses a distinct and highly advantageous set of features that make it a preferred solution for challenging geotechnical engineering projects:

The tightly interwoven structure of high-tenacity polyester yarns gives PET Woven Geotextile exceptionally high tensile strength in both principal directions. This superior strength allows the geotextile to effectively resist substantial tensile forces and distribute significant loads within soil masses, providing critical reinforcement for demanding structures. Furthermore, PET Woven Geotextile typically exhibits a high modulus of elasticity, indicating its stiffness and resistance to deformation under load. This ensures that the reinforcement capacity of the geotextile is mobilized quickly and efficiently, even under significant stress.

Polyester fibers exhibit significantly better creep resistance compared to polypropylene fibers. Creep, the tendency of a material to deform permanently under sustained loading over time, is a critical consideration in long-term reinforcement applications. The superior creep resistance of PET Woven Geotextile ensures minimal deformation and maintained reinforcement capacity over the design life of critical structures such as permanent retaining walls, high embankments, and bridge abutments, providing enhanced long-term stability and reducing the risk of structural settlement or failure.

Polyester offers excellent resistance to a wide range of environmental factors that can degrade geosynthetic materials over time. This includes superior resistance to ultraviolet (UV) radiation compared to standard polypropylene, as well as good resistance to chemical degradation, particularly in acidic soil environments where PET often outperforms PP. This inherent durability ensures the long-term performance and reliability of PET Woven Geotextile in demanding geotechnical conditions, contributing to the extended service life of the reinforced structures.

The woven construction of PET Woven Geotextile provides excellent dimensional stability, meaning the fabric maintains its shape and structural integrity under stress and over time. This is crucial in reinforcement applications where the geotextile must maintain its intended geometry within the soil mass to effectively resist deformation and prevent structural instability throughout the project’s lifespan.

The weaving process allows for precise control over the pore size within the PET Woven Geotextile fabric, quantified as the Apparent Opening Size (AOS). This controlled porosity enables the geotextile to function effectively as a filter, allowing water to pass through while retaining soil particles. The specific AOS can be engineered to meet the filtration requirements of different soil types and drainage conditions, preventing clogging and ensuring the long-term performance of drainage systems associated with reinforced structures.

Polyester has a higher melting point and better resistance to elevated temperatures compared to polypropylene. This can be an advantage in certain construction scenarios or in environments where temperature fluctuations might be a concern, ensuring the integrity of the reinforcement material.

PET Woven Geotextile is available in a comprehensive range of exceptionally high tensile strengths, often exceeding those of standard PP woven geotextiles. This wide selection allows engineers to choose the most appropriate grade to precisely match the specific mechanical and performance demands of their most critical projects, optimizing structural integrity and ensuring the safety and longevity of the infrastructure.

The utilization of PET Woven Geotextile in civil engineering projects offers several compelling advantages, particularly in demanding and critical applications:

The superior creep resistance and high tensile strength of PET Woven Geotextile ensure exceptional long-term performance and dimensional stability, even under high, sustained loads. This is a critical advantage in permanent reinforcement applications where structural integrity over the design life of the project is paramount, minimizing the risk of settlement, deformation, and failure.

The unmatched tensile strength and high modulus of PET Woven Geotextile provide optimal reinforcement for critical infrastructure projects such as high retaining walls, steep slopes supporting significant loads, bridge abutments, and embankments over weak foundations. This enhanced reinforcement capacity ensures the stability and safety of these vital structures.

The superior resistance of polyester to ultraviolet (UV) radiation and certain chemical environments, particularly acidic soils, ensures the long-term durability and reliability of PET Woven Geotextile in challenging geotechnical conditions, contributing to the extended service life of the reinforced structures and minimizing the need for costly repairs or replacements.

The high modulus of elasticity and excellent creep resistance of PET Woven Geotextile result in minimal deformation under both short-term and long-term loading conditions. This ensures the consistent and reliable performance of the reinforcement system, maintaining the intended structural geometry and preventing excessive movement.

The unique combination of exceptional strength, superior creep resistance, and excellent durability makes PET Woven Geotextile a versatile and reliable solution for a wide range of demanding geotechnical applications where long-term performance and structural integrity are critical, providing engineers with a high-confidence material for their most challenging projects.

While its primary role is often reinforcement, PET Woven Geotextile also offers effective separation between dissimilar soil layers, preventing their intermixing and maintaining the integrity of engineered fills. Furthermore, its controlled AOS allows for effective filtration in drainage systems associated with reinforced structures, preventing the migration of fines and ensuring long-term drainage efficiency.

Yes, Pet Woven Geotextile is designed to be permeable, allowing water to pass through while retaining soil particles. Its woven structure features controlled pore sizes (175–1200 microns), which enable water flow rates of up to 850 liters/m²/sec, depending on the geotextile’s specifications. This permeability makes it ideal for applications like drainage, filtration, and erosion control, where water must move freely without causing soil loss or clogging.

The geotextile’s ability to manage water flow is enhanced by its resistance to biological and chemical degradation, ensuring consistent performance in wet environments. For projects requiring both filtration and reinforcement, Pet Woven Geotextile provides an optimal balance of strength and hydraulic properties.

The choice between PP (polypropylene) and PET (polyester) woven geotextiles hinges on the specific demands of the civil engineering project. While both offer soil stabilization, reinforcement, and separation, their distinct material properties lead to key differences in performance and suitability. Here’s a deeper dive into their differences:

| Feature | PP Woven Geotextile | PET Woven Geotextile |

|---|---|---|

| Raw Material | Polypropylene | Polyester (Polyethylene Terephthalate) |

| Density | Lower | Higher |

| Tensile Strength | Generally lower | Generally higher |

| Elongation | Higher | Lower |

| Creep Resistance | Lower | Superior |

| UV Resistance | Generally better (can be enhanced in PET) | Good (often enhanced with additives) |

| Acid Resistance | Excellent | Good to Mineral Acids |

| Alkali Resistance | Excellent | Good to Weak, Degrades in Strong |

| Temperature Resistance | Lower melting point, susceptible to shrinkage | Higher melting point, better resistance |

| Abrasion Resistance | Generally lower | Generally higher |

| Biological Resistance | Excellent | Excellent |

| Cost | Generally lower initial cost | Generally higher initial cost |

| Primary Use Cases | General reinforcement, separation, filtration | High-strength reinforcement, long-term stability |

PET woven geotextiles are used in a variety of construction, civil engineering, and environmental applications. Some of the most common uses include:

BPM Geosynthetics, as one of the largest geo liner manufacturers and companies in China, is renowned for strong geomembrane liners and geotextile liners manufacturing alibilities. We offer complete range of best quality geomembranes, geotextiles and related geosynthetic liners at competitive factory price for your environmental, civil engineering and mining applications.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbanes, geotextiles or other geosynthetic liner products or services, please fill in the form, we are always here repond to your inquiries as soon as possible.