Share:

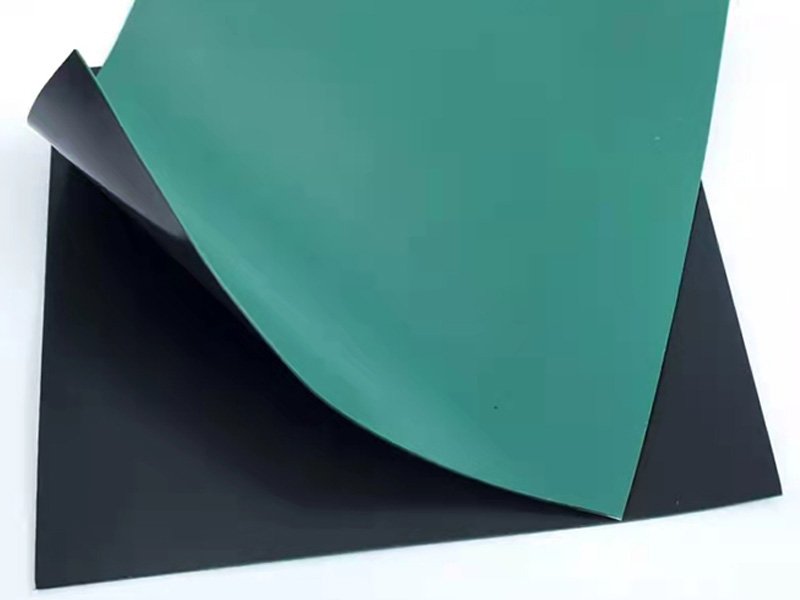

An LLDPE geomembrane liner is a high-performance synthetic membrane made from linear low-density polyethylene. It is designed for superior containment in environmental, agricultural, and civil engineering projects. Renowned for its exceptional flexibility, puncture resistance, and cost-effectiveness, this liner is a preferred choice for applications requiring adaptability to irregular surfaces, such as aquaculture ponds, landfill caps, and wastewater lagoons. As the leading geo liner manufacturers, BPM Geosynthetics provides LLDPE geomembrane liners that meet ASTM D7176 and GRI GM17 standards, ensuring top-tier quality and compliance.

Looking For Best geomembrane LLDPE Liners At Best Factory Price? BPM Geosynthetics Is The Trusted Geomembrane And Geotextile Manufacturer and Factory offering Best Solution for Global Customers.

LLDPE (Linear Low-Density Polyethylene) geomembrane liners are flexible, durable sheets used for containment in a wide array of applications. Manufactured from premium-grade polyethylene resins, these liners offer exceptional resistance to chemicals, UV radiation, and punctures, making them a superior choice for various industries. LLDPE geomembranes are characterized by their linear molecular structure, which provides enhanced tensile strength and flexibility compared to other polyethylene materials. This unique structure allows LLDPE liners to conform to uneven surfaces and withstand significant differential settlement, ensuring long-term performance and reliability. They typically consist of approximately 97.5% polymer and 2.5% additives like carbon black, antioxidants, and heat stabilizers to enhance their properties and lifespan.

| PROPERTIES | Test method | Unit | BPM50 | BPM75 | BPM100 | BPM150 | BPM200 | BPM250 |

| Thickness (minimum average) | ASTM D 5199 | millimeters | 0.5 | 0.75 | 1 | 1.5 | 2 | 2.5 |

| Thickness (lowest individual reading) | ASTM D 5199 | millimeters | 0.45 | 0.67 | 0.9 | 1.35 | 1.8 | 23 |

| Density (min.) | ASTM D 1505 | g/cm3 | 0.92 | 0.92 | 0.92 | 0.92 | 0.92 | 0.92 |

| Tensile properties (minimum average) | ASTM D 6693 | |||||||

| Strength at rest | kN/m | 14 | 20 | 27 | 40 | 55 | 66 | |

| Elongation at break | % | 800 | 800 | 800 | 800 | 800 | 800 | |

| Tear resistance (minimum average) | ASTM D 1004 | north | 50 | 70 | 100 | 150 | 200 | 250 |

| Puncture resistance (minimum average) | ASTM D 4833 | north | 120 | 190 | 250 | 370 | 500 | 620 |

| Carbon black content (minimum average) | ASTM D 1603 | % | 2 | 2 | 2 | 2 | 2 | 2 |

| Carbon black dispersion (minimum average) | ASTM D 5596 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 |

| Brittleness at low temperatures | ASTM D 746 | C | < -77 | < -77 | < -77 | < -77 | < -77 | < -77 |

| Oxidative induction time (OIT) (minimum average) | ASTM D 3895 | minutes | 100 | 100 | 100 | 100 | 100 | 100 |

| Melt flow index (190 °C, 2.16 kg) | ASTM D 1238 | grams/10 minutes | < 1.0 | < 1.0 | < 1.0 | < 1.0 | < 1.0 | < 1.0 |

| 2% module | ASTM D 5323 | kN/m | 210 | 370 | 420 | 630 | 840 | 1050 |

| Dimensional stability (100˚C, 1 hour) | ASTM D 1204 | % | ± 1 | ± 1 | ± 1 | ± 1 | ± 1 | ± 1 |

| Axisymmetric rupture deformation | ASTM D 5617 | % | 56 | 56 | 56 | 56 | 56 | 56 |

| Brittleness at low temperatures | ASTM D 746 | C | < – 77 | < -77 | < -77 | < -77 | < -77 | < -77 |

LLDPE geomembrane liners boast a unique combination of properties that make them an ideal choice for containment applications:

LLDPE geomembrane liners offer significant advantages for project efficiency, environmental protection, and cost savings:

These benefits make LLDPE liners an economical and sustainable solution for containment projects worldwide.

LLDPE geomembrane liners are available in a range of thicknesses to meet diverse project requirements, typically from 0.3 mm to 3.0 mm. Thickness is expressed in millimeters (mm), mils (1 mil = 0.0254 mm), and microns (1 micron = 0.001 mm). Standard thicknesses include:

Thicker liners (e.g., 60+ mils) provide 25% greater puncture resistance (300 N, ASTM D4833) and 40% improved stress crack resistance, per GRI GM17 standards. Selection depends on subgrade conditions, load stress, and regulatory requirements, with 40-mil liners being the most versatile for cost and performance.

LLDPE and PVC geomembrane liners serve similar containment purposes but differ in composition, performance, and application suitability:

Recommendation: Choose LLDPE for large-scale, chemically aggressive, or cold-climate projects requiring flexibility and UV resistance; select PVC for smaller, neutral-pH applications needing high conformability.

LLDPE geomembrane liners are versatile, addressing critical containment needs across multiple industries:

Used in fish and shrimp ponds, 20–40 mil liners prevent 98% water loss and maintain water quality, boosting yields by 15% in regions like Indonesia.

Provides 99.8% leachate containment in municipal and hazardous waste landfills, meeting EPA Subtitle D standards with 40–60 mil liners.

Lines irrigation canals, reservoirs, and golf course ponds, reducing seepage by 95% and supporting water conservation in drought-prone areas.

Contains aggressive effluents in treatment lagoons, with 60-mil liners ensuring 96% chemical resistance for long-term performance.

Used in tailings ponds and heap leach pads, 60–80 mil liners resist acidic leachates and withstand 25% higher puncture risks.

Supports methane capture in dairy farm ponds and manure storage, with 40-mil liners offering 90% impermeability.

Prevents oil and chemical spills in industrial facilities, using 40–60 mil liners for 98% containment efficiency.

These applications underscore LLDPE’s adaptability to flexible, environmentally sensitive containment needs.

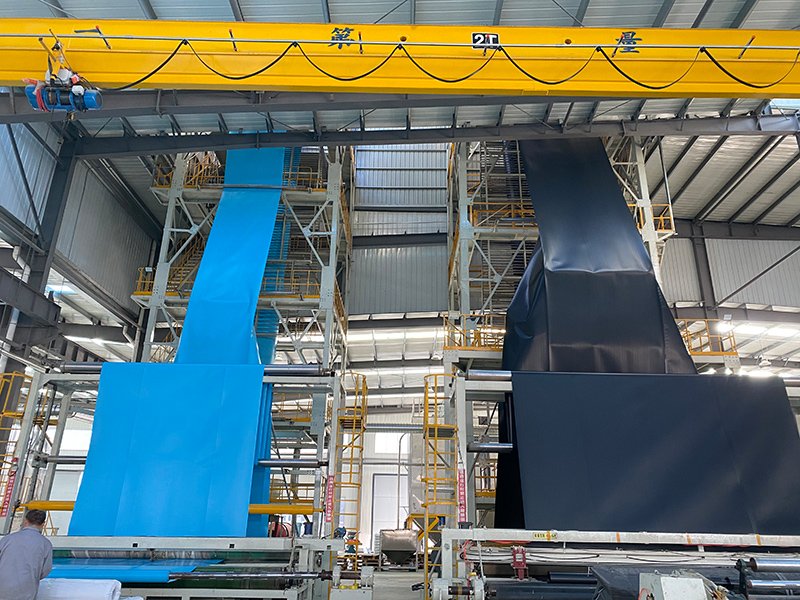

BPM Geosynthetics, as one of the largest geo liner manufacturers and companies in China, is renowned for strong geomembrane liners and geotextile liners manufacturing alibilities. We offer complete range of best quality geomembranes, geotextiles and related geosynthetic liners at competitive factory price for your environmental, civil engineering and mining applications.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbanes, geotextiles or other geosynthetic liner products or services, please fill in the form, we are always here repond to your inquiries as soon as possible.