Share:

PP woven geotextile is specially designed and manufactured by weaving polypropylene fibers to form a strong and stable fabric structure. It has unmatched strength, durability, and versatility for a wide range of applications in civil engineering and construction projects. From road construction to coastal protection, its ability to reinforce, separate, filter, and control erosion makes it an essential geo liner material for civil engineering projects. With customizable specifications, cost-effectiveness, and environmental resilience, PP Woven Geotextile delivers long-term value and performance.

By choosing PP woven geotextile, you can ensure enhanced stability, durability, and performance in your engineering projects. If you are involved in civil engineering or construction and seeking a high-quality, cost-effective geotextile solution, consider the benefits of PP woven geotextile.

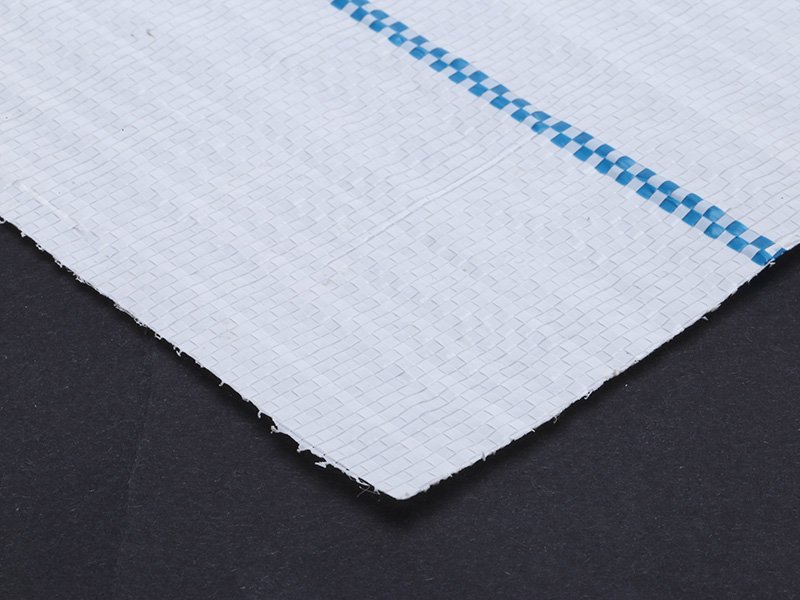

PP Woven Geotextile, also known as polypropylene woven geotextile fabric, is a permeable geosynthetic material crafted from high-quality polypropylene (PP) yarns. These yarns are woven together using advanced industrial looms to create a robust, textile-shaped fabric with exceptional tensile strength and stability. Unlike nonwoven geotextiles, which are bonded through needle-punching or heat, woven geotextiles are manufactured by interlacing two or more sets of yarns (warp and weft) in a structured pattern, typically plain, twill, or satin weaves. This weaving process results in a material that excels in separation, reinforcement, filtration, and erosion control applications.

PP Woven Geotextiles are engineered to improve the performance of soil, rock, or other geotechnical materials in civil engineering projects. Their ability to withstand harsh environmental conditions, including chemical exposure and UV radiation, makes them a preferred choice for infrastructure projects worldwide. Available in various tensile strengths, woven structures, and sizes, PP Woven Geotextiles can be tailored to meet the specific demands of road construction, embankments, and coastal protection projects.

| Property | BPM20-15 | BPM30-20 | BPM40-28 | BPM50-35 | BPM60-42 | BPM80-56 | BPM100-70 |

|---|---|---|---|---|---|---|---|

| Breaking Strength in MD KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

| Breaking Strength in MD KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

| Elongation Rate | 25% | ||||||

| Trapezoidal Tearing Strength, KN >= | 0.2 | 0.27 | 0.34 | 0.41 | 0.48 | 0.6 | 0.72 |

| CBR Mullen Burst Strength KN | 1.6 | 2.4 | 3.2 | 4 | 4.8 | 6 | 7.5 |

| Vertical Permeability cm/s | 10-1~10-4 | ||||||

| Sieve Size O90 (O95) (mm) | 0.07~0.50 | ||||||

| Unit Weight (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

| Variation | ±10% | ||||||

PP Woven Geotextile boasts a range of features that make it a standout material in geotechnical applications. Below are the key characteristics that define its performance:

The woven structure of PP Geotextile provides superior tensile strength, with values ranging from 15 kN/m to over 750 kN/m for uniaxial strength and up to 350 kN/m for biaxial strength. This allows it to withstand significant loads and stresses in reinforcement applications.

Despite its strength, PP Woven Geotextile is remarkably lightweight, making it easy to handle, transport, and install. This reduces labor costs and simplifies logistics on construction sites.

Made from virgin polypropylene, PP Woven Geotextile is resistant to soil chemicals, acids, alkalis, and UV radiation. This ensures long-term durability in aggressive environments, such as chemical plants or coastal areas.

PP Woven Geotextiles are available in a variety of weights (100–1200 gsm), widths (1–6 meters), and woven opening sizes. This versatility allows engineers to select the precise specifications needed for their projects.

The woven pattern ensures dimensional stability, minimizing elongation and maintaining structural integrity under load. This makes it ideal for applications requiring consistent performance over time.

The thickness of PP Woven Geotextile varies depending on its weight, tensile strength, and intended application. Thickness is typically measured in millimeters (mm), mils (1 mil = 0.0254 mm), or microns (1 micron = 0.001 mm). Below is a general guide to PP Woven Geotextile thickness:

The thickness directly impacts the geotextile’s tensile strength, permeability, and tear resistance. For precise thickness specifications, consult the manufacturer’s technical data sheet, as variations in weaving patterns and yarn density can influence measurements.=

PP Woven Geotextile offers numerous advantages that make it a cost-effective and reliable choice for geotechnical projects. Here are the key benefits:

Its high tensile strength and low elongation provide excellent reinforcement for soft soils, preventing settlement and enhancing load distribution. This is critical for applications like road subgrades and railway foundations.

PP Woven Geotextile is priced competitively, with costs ranging from $0.30 to $0.70 per square foot, depending on specifications. Its durability and performance reduce maintenance costs over time.

By stabilizing soil and preventing particle migration, PP Woven Geotextile effectively controls erosion on slopes, riverbanks, and coastal areas.

The material’s resistance to biological degradation, chemicals, and UV exposure ensures a long service life, even in harsh conditions.

Its lightweight nature and flexibility simplify installation, reducing labor and equipment costs. Rolls can be cut and stitched to fit specific project requirements.

With a range of tensile strengths, thicknesses, and woven patterns, PP Woven Geotextile can be tailored to meet diverse engineering needs, from lightweight separation to heavy-duty reinforcement.

Textured PP Woven Geotextile is not waterproof but is designed to be permeable, allowing water to pass through while retaining soil particles. The woven structure creates controlled pore sizes (175–1200 microns) that facilitate water flow while preventing clogging. This permeability is essential for applications like drainage, filtration, and erosion control, where water must move freely without compromising soil stability.

While PP Woven Geotextile is not waterproof, its polypropylene composition ensures it does not absorb water, maintaining its mechanical properties in wet conditions. For projects requiring impermeability, such as landfill liners, PP Woven Geotextile can be paired with geomembranes to create a composite system that prevents water seepage.

Understanding the differences between filament nonwoven and PP Woven Geotextile is crucial for selecting the right material for your project. Below is a detailed comparison:

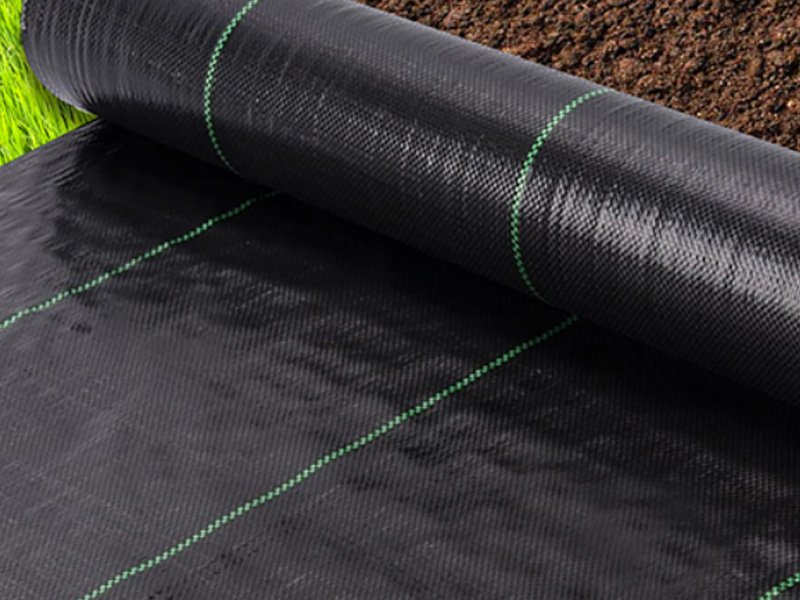

PP Woven Geotextile is widely used across various civil engineering and environmental projects due to its versatility and durability. Below are the primary applications:

PP Woven Geotextile is used for subgrade stabilization, preventing the mixing of dissimilar soils and distributing loads evenly. This extends the lifespan of roads, railways, and airport runways.

Its high tensile strength and erosion control capabilities make it ideal for stabilizing shorelines, riverbanks, and embankments against wave action and water flow.

In embankment projects, PP Woven Geotextile reinforces soft soils, preventing settlement and enhancing structural stability.

When paired with geomembranes, PP Woven Geotextile provides filtration and separation in landfill liners, ensuring long-term environmental protection.

The geotextile’s permeability supports efficient drainage in trenches, retaining walls, and sports fields, preventing water buildup and soil erosion.

PP Woven Geotextile stabilizes slopes in highway and railway projects, reducing the risk of landslides and soil erosion.

BPM Geosynthetics, as one of the largest geo liner manufacturers and companies in China, is renowned for strong geomembrane liners and geotextile liners manufacturing alibilities. We offer complete range of best quality geomembranes, geotextiles and related geosynthetic liners at competitive factory price for your environmental, civil engineering and mining applications.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbanes, geotextiles or other geosynthetic liner products or services, please fill in the form, we are always here repond to your inquiries as soon as possible.