Share:

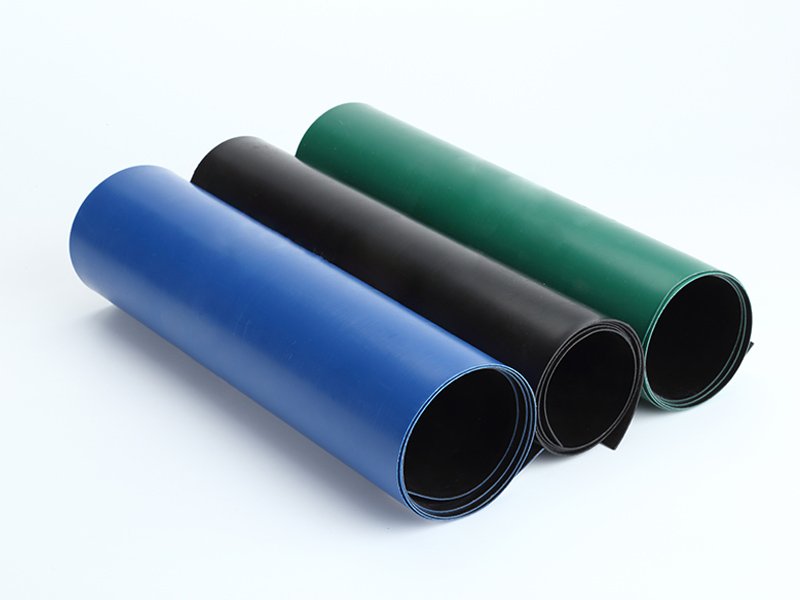

HDPE geomembrane is a low permeability synthetic membrane designed to control fluid or gas migration in geotechnical projects. Renowned for its strength, durability, and chemical resistance, it is an ideal choice for various containment solutions. BPM HDPE geomembranes effectively address a range of barrier needs, making them suitable for applications in environmental protection and industrial containment. BPM HDPE geomembrane is available in thicknesses from 0.5mm to 3.0mm, 10 meters in width, and it meets rigorous standards including 27 kN/m tensile strength (ASTM D6693) and 640 N puncture resistance (ASTM D4833). Our HDPE geomembranes are widely used in civil and environmental engineering projects, ensuring reliable and effective containment solutions.

An HDPE geomembrane is a synthetic, impermeable liner made from high-density polyethylene (HDPE) resin, designed to prevent fluid and gas migration in geotechnical and environmental applications. Manufactured through advanced extrusion processes, this geomembrane boasts a density of 0.941–0.965 g/cm³, granting it exceptional strength and resilience. Unlike softer alternatives, the HDPE geomembrane is a rigid, robust solution widely used in ponds, landfills, mining, and wastewater containment.

BPM Geosynthetics invested 5 million dollars for the state-of-the-art geomembrane manufacturing facilities such as automatic precision production line, automatic feeding system improve efficiency and effectiveness. Our HDPE geomembranes areproduced via flat-die cast or blown-film extrusion, blending HDPE with 2–2.5% carbon black, UV stabilizers, and antioxidants by our 15+ years of expertise and experiences. Available in smooth or textured finishes—textured for slopes (>30° friction angle)—it can include conductive layers for leak detection (ASTM D7240). Heat-welded seams (13 kN/m, ASTM D6392) ensure a seamless, watertight barrier.

The HDPE geomembrane excels with a permeability coefficient of 1×10⁻¹⁷ cm/s, far surpassing clay liners (10⁻⁷ cm/s), and operates in temperatures from -70°C to 110°C . Its versatility and strength make it a go-to choice for demanding containment needs.

| Item | Detailed Item | Unit | Standard | Test frequency | GSO75 | GSO10 | GSO15 | GSO20 | GSO30 |

|---|---|---|---|---|---|---|---|---|---|

Mechanical Properties | Thickness | mm | ASMD5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

| Density | g/cc | ASMD1505/D792 | 90,000kg | 0.94 | |||||

| Tensile Properties | |||||||||

| Yield Strength | KN/m | ASMD6693

Type IV | 9,000 kg | 11 | 15 | 22 | 29 | 44 | |

| Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

| Yield Elongation | % | 13 | 13 | 13 | 13 | 13 | |||

| Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

| Tear Resistance | N | ASMD D1004 | 20,000kg | 93 | 125 | 187 | 249 | 374 | |

| Puncture Resistance | N | ASMD D4883 | 20,000kg | 240 | 320 | 540 | 660 | 960 | |

| Stress Crack Resistance | hr. | ASMD D5397 | per GRI GM-10 | 500 hr. | |||||

| Carbon black content | % | ASMD D4218 | 9,000kg | 2.0-3.0% | |||||

| Carbon black dispersion | ASMD D5596 | 20,000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

| Standard OIT | min | ASMD D3895 | 90,000kg | 100 min | |||||

| High pressure OIT | ASMD D5885 | 90,000kg | 500 min | ||||||

| Oven Aging at 85°C retained after 90 days | % | ASMD D5721 | per each formulation | 55% | |||||

| Standard OIT | ASMD D3895 | 80% | |||||||

| High pressure OIT | ASMD D5885 | 80% | |||||||

| UV Resistance | |||||||||

| High Pressure OIT – % retained after 1600 hrs | % | ASMD D5885 | per each formulation | 50% | |||||

Roll Size | Roll Width | m | 7 | 7 | 7 | 7 | 7 | ||

| Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

| Size stability | % | 2% | |||||||

HDPE geomembranes have a range of features that make them stand out in the geosynthetic market. Below are the key characteristics that define their performance:

HDPE geomembranes are highly resistant to a broad spectrum of chemicals, including acids, alkalis, solvents, and hydrocarbons. This makes them ideal for applications like landfill liners and mining operations, where exposure to corrosive substances is common.

One of the hallmark features of HDPE geomembranes is their low permeability, which prevents the passage of liquids and gases. This impermeability is critical for containing hazardous materials and protecting soil and groundwater from contamination.

Stabilized with UV inhibitors, HDPE geomembranes withstand prolonged exposure to sunlight without degrading. They also perform reliably across extreme temperatures, from freezing cold to intense heat, ensuring consistent performance in diverse climates.

HDPE geomembranes exhibit excellent tensile strength, allowing them to withstand significant mechanical stress without tearing or puncturing. This durability is essential for projects involving heavy loads or dynamic environmental conditions.

Despite their toughness, HDPE geomembranes remain flexible enough to conform to uneven surfaces. They can be heat-welded to create strong, seamless joints, ensuring a continuous barrier that maintains impermeability.

These features collectively make HDPE geomembranes a versatile and reliable choice for a wide range of containment applications, delivering both performance and peace of mind.

The advantages of HDPE geomembranes extend beyond their technical specifications, offering operational and economic benefits that enhance project efficiency. Here’s a closer look at why HDPE geomembranes are a smart investment:

HDPE geomembranes are produced through a streamlined manufacturing process, keeping costs competitive compared to other materials like PVC or EPDM. Their durability reduces the need for frequent replacements, lowering long-term maintenance expenses.

By preventing leaks and contamination, HDPE geomembranes play a critical role in safeguarding ecosystems. They are non-toxic and inert, ensuring no harmful substances leach into surrounding soil or water, making them ideal for environmentally sensitive projects.

HDPE geomembranes are available in large rolls, allowing for rapid deployment over expansive areas. Their weldability enables precise seam construction, minimizing installation errors and ensuring a secure barrier.

From landfills to aquaculture ponds, HDPE geomembranes adapt to diverse project requirements. Their ability to handle varying thicknesses, textures, and environmental conditions makes them a go-to solution for engineers worldwide.

With proper installation and maintenance, HDPE geomembranes deliver consistent performance over decades. Their resistance to degradation ensures they remain effective even in challenging conditions, providing lasting value.

These advantages position HDPE geomembranes as a preferred choice for projects prioritizing sustainability, efficiency, and durability.

The life expectancy of an HDPE geomembrane is a critical consideration for any project, as it directly impacts cost-effectiveness and environmental safety. On average, HDPE geomembranes can last between 20 and 100 years, depending on several factors:

Exposure to UV radiation, extreme temperatures, and chemical agents can influence an HDPE geomembrane’s lifespan. Buried liners, such as those in landfills, often last longer—up to 200 years in mild environments—due to protection from sunlight and weather. Exposed liners, like those in floating covers, typically have a shorter lifespan, around 20-50 years, due to UV and oxidative degradation.

High-quality HDPE geomembranes made from virgin resins with robust stabilizer packages (e.g., antioxidants and UV inhibitors) tend to outlast lower-grade alternatives. Thicker liners (1.5 mm to 3.0 mm) generally offer greater durability than thinner ones, though thickness alone isn’t a definitive factor.

Proper installation is paramount. Poor welding, inadequate subgrade preparation, or mechanical damage during deployment can compromise an HDPE geomembrane’s integrity, shortening its life. Regular inspections and maintenance, such as repairing minor punctures, can extend its service life significantly.

The specific use case affects longevity. For example, HDPE geomembranes in wastewater treatment plants may face constant chemical exposure, while those in irrigation canals may endure less stress. Tailoring the liner’s specifications to the application ensures optimal performance.

Studies, such as those by the Geosynthetic Institute, suggest that modern HDPE geomembranes with advanced formulations can exceed 100 years in unexposed conditions. Even in exposed settings, liners installed in the 1980s have demonstrated service lives of 30-35 years with minimal degradation, showcasing their remarkable endurance.

When choosing a geomembrane, HDPE and PVC are two of the most common materials considered. While both have their merits, HDPE geomembranes often outperform PVC in several key areas, making them a better fit for many projects. Here’s a detailed comparison:

HDPE geomembranes are tougher and more rigid than PVC, offering superior tensile strength and puncture resistance. This makes them ideal for high-stress environments like landfills or mining sites, where mechanical damage is a concern. PVC, while flexible, is softer and more prone to tearing under heavy loads.

HDPE geomembranes excel in resisting a wide range of chemicals, including acids, alkalis, and hydrocarbons, making them suitable for harsh industrial applications. PVC geomembranes, while chemically resistant to some extent, are less effective against certain solvents and hydrocarbons, limiting their use in chemically aggressive environments.

HDPE geomembranes are formulated with UV stabilizers, allowing them to withstand prolonged sunlight exposure without significant degradation. They also perform well across a broad temperature range, from -40°C to 80°C. PVC geomembranes, however, are more sensitive to UV exposure and can become brittle in cold temperatures, reducing their suitability for exposed applications.

HDPE geomembranes typically have a longer service life than PVC, especially in demanding conditions. While PVC liners may last 10-20 years in buried applications, HDPE geomembranes can endure for decades longer, particularly when buried or properly maintained.

HDPE geomembranes are made from polyethylene, which is recyclable and does not rely on plasticizers that can leach over time. PVC geomembranes, on the other hand, often contain plasticizers that may migrate into the environment, raising concerns for long-term ecological safety.

HDPE geomembranes require precise welding techniques but offer strong, reliable seams. PVC geomembranes are easier to handle due to their flexibility, but their seams may be less durable, especially in high-stress environments. For large-scale projects, HDPE’s robustness often outweighs the ease of PVC installation.

While PVC geomembranes are cost-effective and suitable for smaller, less demanding projects, HDPE geomembranes are the go-to choice for applications requiring high strength, chemical resistance, and long-term reliability.

Thickness is a critical parameter for an HDPE geomembrane, balancing strength, cost, and application needs. Here’s a breakdown in mm, mil, and micron (1 mil = 25.4 microns; 1 mm = 1,000 microns):

No | Thickness (mm) | Mil | Micron | Common Use |

1 | 0.5 | 20 | 500 | Small ponds |

2 | 1.0 | 40 | 1,000 | Aquaculture |

3 | 1.5 | 60 | 1,500 | Landfills |

4 | 2.0 | 80 | 2,000 | Mining |

5 | 3.0 | 120 | 3,000 | Industrial |

HDPE geomembrane is a versatile solution across industries, tailored to specific containment challenges.

BPM Geosynthetics is a global leader and manufacturer of geomembranes engineered specifically for your containment systems. We offer complete range of best quality geomembranes at competitive factory price on fast delivery.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

[fluentform id="1"]

When you’re looking for geomemrbane or geosynthetics products or services, we are always here repond to your quote as soon as possible.